Standard Operating Procedure (SOP) for the Calculation of Yield and finalize the Limit at the different stages of drug product processing/manufacturing. This SOP is also applicable for Investigation of out of limit yield obtained during processing.

Calculation of Yield and finalize the Limit

1.0 OBJECTIVE :

-

- To lay down a procedure for fixation of yield and investigation of out of limits yield obtained at various stages of processing of a product.

2.0 SCOPE :

-

- This SOP shall be applicable for all Batch Records (Batch Manufacturing Record and Batch Packaging Record) for Calculation of Yield and finalize the Limit at the different processing stages.

-

- This SOP is also applicable for Investigation of out of limit yield obtained at pharmaceutical drug manufacturing plants.

3.0 RESPONSIBILITY- YIELD CALCULATION :

-

- Officer/ Executive Production: Evaluation of yields and Investigation of out of limit.

-

- Officer / Executive QA: Review of calculation data and Investigation of out of limit obtained.

-

- Head production: Review of Investigation of out of limit result obtained.

-

- Head, Q A: Compliance to SOP

-

- DEFINITION (S)

-

- Yield is a rationale of usable quantity obtained from a process to the actual starting quantity provided.

4.0 PROCEDURE FOR CALCULATION OF YIELD :

-

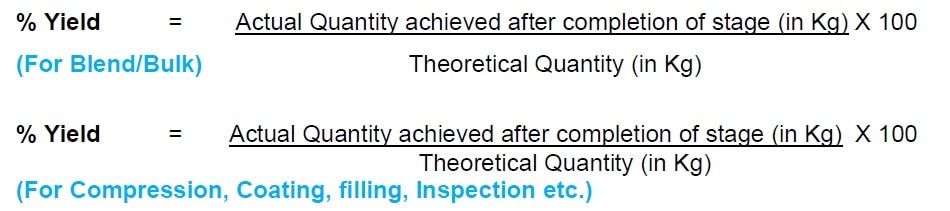

- % Yield (henceforth referred to as Yield) shall be evaluated at each stage were the quantifiable measure of a product is possible.

-

- However, yield shall be evaluated at different stages mentioned below but not limited to, depending on the nature of the process,

-

-

- End of granulation stage/ Dry Mixing

- Sizing / Compaction and Milling

- End of Blending

- Completion of compression/ filling

- End of coating*

- End of packing

- * Yield to be evaluated at each coating process for products where coating to be done in multiple stages (e.g. Seal coating, Polymer coating, Enteric coating, Polishing, Etc.)

-

-

-

Two types of yields shall be evaluated: % actual yield and reconciliation yield.

-

-

- The reconciliation shall be done for each stage.

-

- While undertaking reconciliation, Loss during the process, rejection, samples, and actual quantity shall be evaluated.

| Stage | Parameter | UOM |

| A | Actual batch size of the preceding stage | Kg |

| B | Actual weight of the stage | Kg |

| C | Samples for Analysis (QC + Inprocess) | Kg |

| D | Rejects | Kg |

| E | Loss during process | Kg |

-

- Reconciliation Yield = (B+C+D+E)/A x 100 =………….%

-

- When the packing of a product is done in multiple packs, the complete batch reconciliation shall be done after the completion of the last pack.

-

-

For the New Product :

-

-

- For a new product, the yield limit at each individual stage shall be provided as a tentative limit.

- If it is observed below tentative limits justification/ reasons to be provided in the concerned Batch Record.

-

- This is also applicable for existing / validated products when a major change in the manufacturing process is introduced.

-

- Assigning/ Resetting of limits shall be based on general process knowledge, batch size, sampling due to validation, etc.

-

- If any unwarranted low yield values are observed as that of tentative limits, adequate investigation to be done,

-

- However, the need of investigation depends on the nature of the process and decisions taken by stakeholders.

-

- Tentative limits shall be as per Table 1.

-

- However, limits may be made stringent or loose based on product nature / atypical process/ batch size/ packing types.

Table-1

For Tablets & Capsules (Up to 250,000 units) |

|

| Granulation/ Dry mixing | Not Less than 99.0 % |

| Sizing/ Compaction & Milling | Not Less than 98.5 % |

| Blending stage | Not Less than 98.0 % |

| Compression stage | Not Less than 97.5 % |

| Coating stage | Not Less than 97.0 % |

| Filling Stage | Not Less than 96.5 % |

| Inspection stage | Not Less than 96.0 % |

| Packing stage | Not Less than 95.5 % |

For Tablets & Capsules (> 250,000 units) |

|

| Granulation/ Dry mixing | Not Less than 99.5 % |

| Sizing/ Compaction & Milling | Not Less than 99.0 % |

| Blending stage | Not Less than 98.5 % |

| Compression stage | Not Less than 98.0 % |

| Coating stage | Not Less than 97.5 % |

| Filling Stage | Not Less than 97.0 % |

| Inspection stage | Not Less than 96.5 % |

| Packing stage | Not Less than 96.0 % |

Dry Powder injections |

|

| Blending | Not Less than 99.0 % |

| Filling | Not Less than 98.0 % |

| Packing | Not Less than 97.0 % |

Oral Dry Powder Suspension |

|

| Granulation/ Dry mixing | Not Less than 99.0 % |

| Sizing/ Compaction & Milling | Not Less than 98.5 % |

| Blending stage | Not Less than 98.0 % |

| Filling Stage | Not Less than 97.5 % |

| Packing stage | Not Less than 97.0 % |

-

- The yield for a product shall be fixed after completion of 10 manufacturing batches (excluding the validation batches) or at the time of completion of Product Quality Review (Refer SOP for APQR/PQR), whichever is early.

-

- In case it is fixed after completion of 10 batches, a certificate shall be attached to the Batch document (BMR or BPR) as per the template attached as Annexure-1.

- Where the yield is fixed, any out of limit obtained shall be investigated for possible reasons.

- The investigation shall be done on an unplanned deviation format (Refer SOP for Deviation).

- The head of the Department of Production shall provide a reason for the out of limit yield with corrective and preventive actions.

5.0 ABBREVIATION(S) :

-

- BMR: Batch Manufacturing Record

-

- BPR: Batch Packaging Record

Annexure – I: Yield certificate (template)

The yield of the …………………………………………………………………. (Product Name) has been fixed after completion of 10 consecutive batches ( ) / after completion of Product Quality Review ( ) (tick the appropriate)

The fixed limits are as below

|

Sr. No |

Stage | Previous Limit |

Revised Limit |

| 1. | |||

| 2. | |||

| 3. |

**********************************************END**********************************************

Pingback: Antimicrobial Efficacy Test - Guideline - Pharma Beginners