Standard Operating Procedure (SOP) for Operation and Calibration of Dissolution Test Apparatus (Make- Electrolab) used to measure the drug release of Oral Solid Doses in pharmaceuticals.

This SOP Contains following Topics –

A) Operating Procedure for Electrolab Dissolution Apparatus, Model : TDT-08L 0, TDT-14L, and similar models.

B) Calibration Procedure and Formats for Dissolution Apparatus

SOP for Dissolution Test Apparatus

1.0 PURPOSE:

-

- The purpose of this Standard Operating Procedure (SOP) is to describe the procedure for the Operation and Calibration of Dissolution apparatus (EDT-14Lx & EDT-08Lx).

2.0 SCOPE – SOP FOR DISSOLUTION APPARATUS:

-

- This SOP is applicable for Electrolab make Dissolution Apparatus model (ED T-14Lx & EDT-08Lx) series for the measurement of dissolution, dissolution profile of tablets/capsules and other products in quality control department.

3.0 REFERENCES:

-

- Operation manual of supplied by the manufacturer.

-

- Preparation of Internal and External (Third Party) Calibration Schedule and Calibration Practices.

-

- USP/IP (Dissolution <711>)

4.0 RESPONSIBILITY – SOP FOR DISSOLUTION APPARATUS:

-

-

Analyst shall be responsible for :

-

-

- Operation of the Dissolution Apparatus as per SOP.

-

- Calibration of the Dissolution Apparatus as per SOP.

-

- Maintaining of the log book, calibration record, history card.

-

-

Quality Control Head or Designee shall be responsible for:

-

-

- Approval of the calibration of Dissolution Apparatus verifying against SOP.

-

- Training to the all concerned persons before implementing the SOP.

-

- To execute the Out of calibration in case of calibration failure and in case of breakdown intimate to the Quality Head.

-

- Ensure the operation and calibration of the Dissolution Apparatus is carried out as per SOP.

-

- Ensure proper documentation as per SOP.

-

-

Quality Assurance shall be responsible for:

-

-

- To ensure the implementation of the system as per SOP.

5.0 ABBREVIATIONS & DEFINITION:

-

- GM : Geometric Mean

-

- IP : Indian Pharmacopoeia

-

- NMT : Not more than

-

- QA : Quality Assurance

-

- QC : Quality Control

-

- RPM : Revolution per minute

-

- USP: United States Pharmacopoeia

-

- DEFINITION:

-

- Standard Operating Procedure (SOP):– A written authorized procedure, which gives instructions for performing the operation.

6.0 PROCEDURE – SOP FOR DISSOLUTION APPARATUS:

-

General Procedure for handling of Dissolution Apparatus :

-

- For the entry of usage of the Dissolution Apparatus follow the procedure as per SOP “Instrument/Equipment usage logbook”.

-

- In case of any maintenance of Dissolution Apparatus, follow the procedure as per SOP “ Maintenance of Laboratory Instruments”.

-

- Maintain the third party calibration schedule and the Internal calibration schedule for the Dissolution Apparatus as per SOP “Preparation of Internal and External (Third Party) Calibration Schedule and Calibration Practices”.

-

- In case of noticing any calibration results not within the specified limit, follow the SOP of “Handling Out of Calibration”.

-

Dissolution Apparatus Set-up :

-

- Ensure that the all-Electrical cables are connected properly.

-

- Switch on the Power switch provided on the rear side of EDT-14LX the Dissolution Apparatus will initialize by displaying a power flash screen which will flash once.

-

- After the power flash screen an Idle screen will be displayed showing the last protocol no. selected, RPM, Bath temperature, and Temperature by external probe. Date, time, Menu and Prepare.

-

- Raise the Dissolution Apparatus by pressing the Lift UP key provided on the front panel of EDT-14LX .

-

- Fill the bath with distilled water till the bottom of the Inlet Nozzle. Once the tube of the inlet nozzle is filled with water, ensure the priming of the pump. Then fill water till the level marked.

-

- Place the test vessels filled with the media, in the respective positions.

-

- Set the test parameters & insert the shaft rod as per the method selected.

-

- Lower the stirrer unit by pressing the down arrow key from the front panel.

-

- Press prepare key, for the attainment of temperature.

-

- To attain a constant temperature throughout the vessel start the RPM with paddle/basket attached to the spindle

-

- After getting the desired temperature in each vessel, the ready indication on the front panel will glow green.

-

-

Controls of Dissolution Apparatus:

-

-

- The front panel controls include the following keys :

-

-

- F1: Perform the function indicated at display

-

-

-

- F2: Perform the function indicated at the display.

-

-

-

- F3: Perform the function indicated at the display.

-

-

-

- RPM: To set the RPM for a particular product.

-

-

-

- [TEMP]: Temp. key to set the desired temp. for test & to start the temp. controller

-

-

-

- Alphanumeric keypad: The alphanumeric keypad to enter the value & alphabet.

-

-

-

- [START]: To start the test

-

-

-

- [STOP]: To abort the test.

-

-

-

Parameters Setting of Dissolution Apparatus:

-

-

- RPM setting:

-

- In this parameter revolution per minute of the shaft are set F1 & F3 keys are active to turn on or off the stirrer.

-

- Press RPM key from the front panel a RPM screen will be displayed.

-

- Then Press the Numeric key to set the required RPM.

-

- Press the ESC key to register the value and to come out of the RPM mode.

-

- For Starting / Stopping of Spindle rotation, press RPM key from front panel a RPM screen will be displayed.

-

- Press the F1 key to start or F3 key to stop from the front panel.

-

- Temperature Setting

-

- Press TEMP key from the front panel temperature screen will be displayed.

-

- Then Press Numeric key to set the required temperature (Temperature range 20°C-40°C).

-

- Press Enter key to register the value.

-

- For the Heater ON/OFF Press TEMP key from the front panel, a Temperature screen will be displayed.

-

- Press the F1 key for the heater to be ON or F3 key for the heater to be OFF from the front panel.

-

- Then press the F2 key for the pump on or off.

-

- Press the ESC key to come out of the TEMP.

-

Operational Procedure of Dissolution Apparatus:

-

- Preparation of protocol

-

- The respective protocol details such as Drug name, Media name, RPM, Temperature, Media volume, power fail, Apparatus, Timetable for testing are set in the selected protocol. Limits: Protocols – 20 nos. Steps (in each protocol)1- 24 nos ,pH & sampling information.

-

- Press Menu to prepare a protocol.

-

- Press 2 to enter protocol menu, press 1 to load protocols (Limit: 20 programs)

-

- Select the desired protocol from the idle screen using UP / Down arrow key press enter key.

-

- Press F1 to load next protocol, F2 to load previous protocol and F3 for go back to protocol screen.

-

- Press 3 to view protocol , In view protocol the following details are present .

-

- The respective protocol details such as Drug name, Media name, RPM, Temperature, Media volume, power fail, Apparatus, timetable for testing are set in the selected protocol.

-

- Limits of protocols :Maximum Protocols to be prepared– 20 nos. Steps (in each protocol) –1to 24 nos

-

- The protocol details can be edited using alphanumeric keypad.

-

- In Time table parameters, press Enter key the sampling time interval , action, & total number of samples (1 to 24) can be set as per user requirement using shift & alphanumeric key.

-

- For single time point, action table will have three option media change, sampling & infinity.

-

- For multiple time point, action table will have only two option media change and sampling whereas infinity (min) can be selected after last sample.

-

- Press F3 to save & go back to main menu screen & press F1 to go to the next sampling information.

-

-

To Run the test

-

-

- Press menu then 2 from numeric key ( Three options will be displayed on the screen:-1.Load protocol, 2. Edit Protocol & 3. View Protocol).

-

- Press 1 from numeric key to load the protocol.

-

- Then select the protocol no. by pressing increment or decrement key.

-

- Press F2 to prepare the Dissolution Apparatus for the required condition.Batch number & AR number will be displayed.

-

- Enter the Batch no & A.R. no. by using up/down arrow key .Batch no & A.R. no. can be added up to ten digits.

-

- Press enter key to register the numbers & User Name.

-

- The Dissolution Apparatus will take time to check the link between instrument & syringe /peristaltic pump and sample / fraction collector.

-

- If any error is encountered like volume setting and tray capacity are different the error will be displayed on the dissolution tester screen.

-

- Even if the tray or the waste tray is not aligned properly error message will be displayed.

-

- The heater & circulation pump will start.

-

- The sample collector arm will Initialize and move till the front most position.

-

- The tray identification and settings are checked after that if the feedback is proper as per the settings of user the RUN LED on sample collector and the syringe pump will glow.

-

- After the connection between the Dissolution Apparatus is done, sample collector will initialize & lift Not Park indication will be displayed.

-

- Wait for Temperature indication glow will be display.

-

- When temperature achieved ready indication will glow on front panel .

-

- Tablet drop message will be displayed immediately.

-

- Push the dispenser plate to put the sample in media.

-

-

Then press enter key to start the test.Run screen will be displayed.

-

-

- In the tube from replenishment vessel and will dispense it in the waste position, this will remove air from tube & filled with replenishment media.

-

- Lift the stirrer unit.

-

- The manifold will move to the sampling position one minute prior to the sample interval.

-

- At the sample interval time the syringe pump will auto align to the test vessel position & withdraw the purge (fixed) volume and will dispense in the waste tray, this will eliminate any previous test carry over.

-

- Then the rinse volume (programmed) is withdrawn and it is purged in the waste tray.

-

- The sample collector arm will move to the sampling vials position and dive down.

-

- Now the syringe pump will withdraw the programmed sample volume and will be dispensed in the vials.

-

- If the programmed volume is more than 10ml. upto 25ml. Then the cycle will be repeated.

-

- The syringe sampler will withdraw the replenishment volume from the replenishment vessel and dispensed in the individual sampling vessels. depending on the sample volume this cycle will be repeated.

-

- In the replenishment cycle, the purge volume & the rinse volume is also taken care of and replenished back to test vessel.

-

- The sample collector arm will be returned back to the park position Above sequence will be repeated for the rest of sampling intervals.

-

- The test end indication will be displayed after test over with buzzer sound for 5 seconds.

-

-

To Halt/abort the test – Dissolution Apparatus

-

-

- Press the Stop key from the front panel.

-

- Halt screen with halt time will be displayed and the Halt LED on the front panel will start blinking.

-

- Press F2 / F3 key to Restart / Abort the test.

-

-

Cleaning Cycle of Dissolution Apparatus

-

-

- Cleaning Cycle before start the test

-

- Press menu (From F1 key) , then press 5 from alphanumeric key.

-

- Press 2 from alphanumeric keypad, screen will be displayed with cleaning cycle indication. Put the value 01-04 from alphanumeric keypad, then press F3 for save the parameters.

-

- Press increment key for run & enter key for proceed the test.

-

-

Cleaning Cycle after the test complete

-

-

- The Sample Collector (ESP-124) includes Cleaning Cycle, which is used to clean the syringes after a test is completed.

-

- In this process the entire syringe is filled with cleaning solvent from the vessel and purged into the waste tray of sample collector.

-

- This process is repeated twice.

-

- Check the waste tray in the Sample Collector (ESP –124) is empty or not. It should not overflow.

-

- The entire Offline System should be in communication mode.

-

- Fill the Vessel with cleaning solvent. Place the replenishment tube set in the vessel.

-

- Press the Menu from the front panel of the Dissolution Tester.

-

- Then press 5 Key from main menu to enter in Run screen.

-

- Press 2 from alphanumerical keypad to select cleaning cycle.Press the Enter Key to start the cleaning cycle.

-

- As the Cleaning Cycle starts the ESP-124 Syringe Pump will start drawing cleaning media from the Vessel.

-

- It will draw the cleaning solution until entire Syringe is filled.

-

- Once the complete Syringe is filled the cleaning solution is purged into the waste tray of the sample collector.

-

- This ensures cleaning of the sample collector side tube set.

-

- In second phase cleaning solution is drawn from the replenishment vessel and purged in the sampling vessels for cleaning the sampling side tube set.

-

- This cycle is repeated twice

-

- If ESC key is pressed the sequence is aborted after finishing the current cycle.

-

- The cycle can be repeated depending upon the cleaning requirements.

-

Calibration of Auto sampler Dissolution Apparatus

-

- Take 24 empty glass test tube and 12 bottles. Ensure that the test tubes / Bottles are empty & dry before running the cycle.

-

- Keep 12 test tubes in Ist row and another 12 test tubes in IInd row.

-

- In this Cycle the Electrolab Syringe Pump (ESP-124) draws the rinse volume (3.0 mL) and the sample volume (10.0 mL) one by one and dispenses the volumes at different sample positions in the Electrolab Sample Collector .

-

- The replenishment volume can be collected into collection bottles which can be fitted in the position using the special designed adapters.

-

- Ensure that the Offline System is in communication mode.

-

- To run the validation cycle, Press the MENU button on the front panel of the Dissolution Tester.

-

- Press 5 Key to Enter in RUN option. The menu displays the following.

-

- Then Press the ‘1’ key from alphanumerical keypad. Ignore B.No., A.R. No. & press enter key thrice.

-

- Press Enter key to start the validation cycle.

-

- The screen will change to show validation in progress.

-

-

After checking all communication system.

-

-

- Electrolab Syringe Pump (ESP-124) draws rinse volume and sample volume.

-

- Next it draws the rinse volume and dispenses it at sample collectors first test tube row in the Sample collector.

-

- Then it draws programmed sample volume and dispenses it at the second test tube row in the sample collector.

-

- After this Electrolab Syringe Pump (ESP-124) draws the replenishment volumes from the replenishment vessel.

-

- Attach the bottles in the jar lids at the sampling tube entry position under the dispenser.

-

- Press start. The pump will withdraw the replenishment volume from the vessel and dispense through the sampling tubes in the bottles connected at the ports.

-

- The bottles & tubes can be taken out after the process is over .

-

- Measure the dispensed volume (in mL ) in Rinse volume, sample volume and replacement volume by using calibrated graduated cylinder.

-

- Record the observations as per Annexure 3 for EDT-14LX dissolution apparatus.

-

- Acceptance Criteria: ± 0.1 mL

-

- Frequency of Calibration: Once in three and after any major maintenance job. Make necessary entries in the instrument usage logbook.

-

-

Calibration Procedure of Dissolution Apparatus

-

-

- Mechanical calibration – Dissolution Apparatus

-

- Leveling check

-

- Place a vial bubble apparatus on the each side ( i.e. On four sides front, rear, left and right) of the Dissolution testing apparatus and ensure bubble is in center.

-

- If bubble is not in the center adjust with the help of screws at the bottom of the Dissolution Apparatus.

-

- Record the observation (satisfactory / Not satisfactory) in Annexure- 1.

-

- Calibration frequency : Quarterly ± 7 days

-

- By Digital Protractor

-

- Calibration frequency : Three month ± 3 days Verify the Bench top levelness and Base Plate (Vessel support plate) levelness

-

- Measure the inclination on the each side ( i.e. On four sides front, rear, left and right) for Bench Top and for Base plate.

-

- The inclination should be not more than 1° for Bench top.

-

- The inclination should be not more than 0.5° for Base plate.

-

- Record the readings in Annexure-1.

-

- Calibration frequency : Quarterly ± 7 days

-

- If leveling is not satisfactory for Base plate, adjust the level by rotating the adjusting screws on the feet of the assembly.

-

-

Alignment verification by Digital protractor

-

-

- Shaft Verticality

-

- Measure the verticality of paddle shaft and basket shaft in the dissolution assembly.

-

- Vessel verticality

-

- Measure the verticality of vessel in the dissolution assembly.

-

- Take the measurement on the vessel inner surface.

-

- The reading on a vertical surface should be 90° ± 0.5°

-

- Record the readings in Annexure-1

-

-

RPM Calibration – Dissolution Apparatus

-

-

- Switch on the mains.

-

- Set the rpm to 50 as per procedure given in start up.

-

- Start the stirrer and measure the RPM either manually or by using a calibrated tachometer.

-

- Record the values.

-

- Similarly calibrate the Dissolution Apparatus for 100 and 200 RPM and record. Tabulate the results.

-

- Calibration frequency : Quarterly ± 7 days.

-

-

Temperature Calibration – Dissolution Apparatus

-

-

- Switch on the mains

-

- Set the temperature to 37.0°C by following temperature setting procedure given in Start up.

-

- Put 900ml water in each vessel. Allow the Dissolution Apparatus to stabilize for for achieving the temperature.

-

- Using a calibrated thermometer check the temperature of each bowls

-

- All bowls should show 37 ± 0.5 °C

-

- Record the results in Annexure-I .

-

- Calibration frequency : Quarterly ± 7 days

-

Checking of Centering, wobbling, and distance – Dissolution Apparatus

-

- Wobbling

-

- Fix the paddle/basket apparatus to the Dissolution Apparatus, lower the apparatus.

-

- Fix the wobbling meter on the top of the bowl.

-

- The needle of wobbling meter should touch to the surface of the paddle shaft or lower edge of basket apparatus.

-

- Measure the wobbling reading on the meter.

-

-

Distance from the inside bottom of the jar to the bottom of the basket/paddle

-

-

- Fix the paddle/basket apparatus to the Dissolution Apparatus, lower the apparatus.

-

- Insert the vernier calipers or Depth gauze inside the jar between the bottom of the jar and the bottom of the paddle/basket.

-

- Measure the reading.

-

- Centering

- Align two halves of centering device and gently plug into vessel and paddle / Basket shaft. It should be fit exactly.

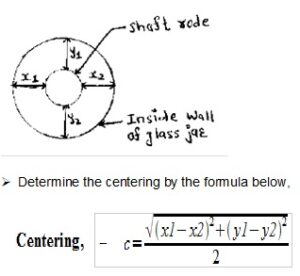

- Measure the distance of center shaft from all four directions in mm as x1,x2,y1 & y2 as shown in figure below,

-

- Limit : NMT 2 mm.

-

- Adjust & record the centering, if the setting is disturbed.

-

- Repeat the above procedure for all the vessels.

-

- Calibration frequency : Quarterly ± 7 days.

-

-

Chemical calibration of Dissolution Apparatus

-

-

- Performance check by USP Prednisone Tablets (Disintegrating Type) for EDT-14LX (Apparatus Suitability Test) (Annexure-2)

Calibration frequency : Six month ± 15 days

-

-

Verification of physical parameters of Dissolution Apparatus

-

-

- At the time of new receipt or at the time of replacement, measure and record the physical parameters of paddle, basket and glass jar.

-

- Record the dimensions in Annexure-3. Verification of Physical parameters

-

- Vibration of the Dissolution Apparatus is checked by vibration meter as a preventive measure of Dissolution Apparatus.

-

- Perform the calibration of peak vessel as per calibration procedure of molded bottom vessel.

-

- The calibration of Dissolution jar no. 13 & 14 is not performed but can be used for dissolution of placebo or can be used to fill the media for replacement.

7.0 ANNEXURES – CALIBRATION OF DISSOLUTION APPARATUS:

Annexure 1: Dissolution Apparatus Calibration Record (Quarterly)

| Instrument Name | Dissolution Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Quarterly ±7 days | |

| Calibrated on | Next calibration due on | ||

| Instrument Used | Code No. | Calibration valid upto |

| Digital Protractor | ||

| Spirit level | ||

| Tachometer | ||

| Thermometer |

Leveling Procedure

By spirit level

Place a level gauge at each side (i.e. on front, rear, left and right) of the Dissolution Apparatus base plate and ensure the bubble is in center. If bubble is not in the center adjust with the help of screws at the bottom of the instrument.

Observation:____________

Acceptance criteria: The Bubble shall be in center.

Conclusion: Leveling is satisfactory / Not satisfactory.

By Digital protractor

Verify the Bench top levelness and Base Plate (Vessel support plate) levelness.

Measure the inclination on the each side ( i.e. On four sides front, rear, left and right) for Bench Top and for Base plate.

If leveling is not satisfactory for Base plate, adjust the level by rotating the adjusting screws on the feet of the assembly.

Observation:

| Observed reading at location | Limit | ||||

| Front | Rear | Left | Right | ||

| Bench Top Inclination | NMT 1° | ||||

| Base Plate Inclination | NMT 0.5° | ||||

Conclusion: Leveling is within/ out of limit

Alignment verification

Shaft verticality

Measure the verticality of paddle shaft and basket shaft in the dissolution assembly.

Observation:

| Observed reading | Limit | ||||||||||||

| Shaft No. # | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| Paddle shaft | 90°±0.5° | ||||||||||||

| Basket shaft | 90°±0.5° | ||||||||||||

Conclusion : Shaft verticality is within / out of limit

Vessel Verticality

Measure the verticality of vessel in the dissolution assembly. Take the measurement on the vessel inner surface.

Observation:

| Observed reading | Limit | ||||||||||||

| Vessel | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 90°±0.5° | |||||||||||||

Conclusion : Shaft verticality is within / out of limit

RPM Calibration

| Sr. No. | Set Speed (RPM) | RPM Observed | Limit |

| 1. | 50 | 48 – 52 | |

| 2. | 100 | 96 – 104 | |

| 3. | 200 | 192 – 208 |

Conclusion : Shaft verticality is within / out of limit

Temperature Calibration

Place the vessels containing 900mL of water . Set the temperature to 37.0°C. Allow the instrument to stabilize.

Verify the temperature in each 14 vessel.

Observation:

| Observed value (°C) for each vessel | Limit | ||||||||||||||

| Temperature

Set value |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

| 37±0.5°C | |||||||||||||||

Conclusion : Shaft verticality is within / out of limit

Remark : The instrument is calibrated & qualified/Out of calibration & not qualified for use.

Annexure 2: Dissolution Apparatus Calibration Record (Half Yearly)

| Instrument Name | Dissolution Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Quarterly ±15 days | |

| Calibrated on | Next calibration due on | ||

Checking of Centering, wobbling and Distance

| Equipments Used for calibration | Code No. | Valid upto |

| Centering kit | ||

| Wobble meter | ||

| Depth gauge |

Procedure for Wobbling measurement

- Fix the paddle/basket apparatus to the instrument, lower the apparatus. Fix the wobbling meter on the top of the bowl. The needle of wobbling meter should touch to the surface of the paddle shaft or lower edge of basket apparatus. Measure the wobbling reading on the meter.

Distance from the inside bottom of the jar to the bottom of the basket/paddle

- Fix the paddle/basket apparatus to the instrument, lower the apparatus. Insert the vernier calipers or Depth gauge inside the jar between the bottom of the jar and the bottom of the paddle/basket. Measure the reading.

Centering

- Align two halves of centering device and gently plug into vessel and paddle / Basket shaft. It should be fit exactly.

- Measure the distance of center shaft from all four directions in mm as x1,x2,y1 & y2 as shown in figure below,Determine the centering by the formula below,

- Limit : NMT 2 mm.

Observation table:

| Test unit | Vessel centering (c ) | Paddle wobble | Basket wobble | D1’mm | D2’mm | ||||

| USP standards | NMT 2 mm | Limit : NMT 0.5 mm | NMT 1.0 mm | 25.0±2.0 mm | |||||

| x1 | x2 | y1 | y2 | c | |||||

| 1. | |||||||||

| 2. | |||||||||

| 3. | |||||||||

| 4. | |||||||||

| 5. | |||||||||

| 6. | |||||||||

| 7. | |||||||||

| 8. | |||||||||

| 9. | |||||||||

| 10. | |||||||||

| 11. | |||||||||

| 12. | |||||||||

| 13. | |||||||||

| 14. | |||||||||

| D1’ | Distance between the bottom edge of the blade to the lowest inner surface of the bowl |

| D2’ | Distance between the bottom edge of the basket to the lowest inner surface of the bowl. |

Annexure 3: Calibration of Auto Sampler.

| Instrument Name | Dissolution Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Quarterly ±15 days | |

| Calibrated on | Next calibration due on | ||

A ) Rinse Volume : Measure the dispensed volume by measuring graduated cylinder & note down the observation in the below table :

| Vessel No. | Volume Dispensed (in ml) | Limit (in ml) |

| 1 | 3±0.1 | |

B ) Sample Volume : Measure the dispensed volume by measuring graduated cylinder & note down the observation in the below table :

| Vessel No. | Volume Dispensed (in ml) | Limit (in ml) |

| 1 | 10±0.1 | |

C ) Replacement Volume : Measure the dispensed volume by measuring graduated cylinder & note down the observation in the below table :

| Vessel No. | Volume Dispensed (in ml) | Limit (in ml) |

| 1 | 13±0.1 | |

| 2 | 13±0.1 |

———————————————————–END————————————————————–