SOP for Operation and Calibration of Total Organic Carbon (TOC) analyzer. This measurement is proportional to the carbon in the sample. Carbon dioxide shows a unique adsorption spectrum when IR energy passes through it.

Operation and Calibration of Total Organic Carbon (TOC) Analyzer

1.0 PURPOSE:

-

- To lay down the procedure for Operation and Calibration of Total Organic Carbon (TOC) Analyzer.

2.0 SCOPE:

-

- This Standard Operating Procedure is applicable at the Quality Control Department of Pharmaceuticals Manufacturing plant.

3.0 REFERENCES:

-

- In – house

-

- Manual of TOC-VCSH, Shimadzu, Japan.

4.0 RESPONSIBILITY:

-

- Officer or Executive of the QC department shall be responsible for the preparation of new or revision of existing SOPs.

-

- Head of the department/designee of respective areas & QA shall be responsible for reviewing the SOPs.

-

- Plant Head and Head-Quality shall be responsible for the approval of SOP.

-

- QA shall be responsible for the distribution and control of SOPs to various departments.

5.0 ABBREVIATIONS USED IN SOP FOR TOTAL ORGANIC CARBON (TOC):

-

- ASI: Automatic Sample injector

- ASI: Automatic Sample injector

-

- C: Carbon

-

- CC: Change Control

-

- cc: Centimeter cube

-

- CO2: Carbon Dioxide

-

- KHP: Potassium hydrogen phthalate

-

- IC: Inorganic Carbon

-

- ID : Identification

-

- IR: Infra-Red

-

- Mg/L: Milligram per liter

-

- NPOC: Nonpurgeable organic carbon

-

- NDIR: Non-Dispersive Infrared Radiation

-

- ppb: Parts per billion

-

- ppm : Parts Per million

-

- SD: Standard deviation

-

- TOC: Total Organic Carbon

-

- UV : Ultra–Violet

6.0 PROCEDURE – OPERATION OF TOTAL ORGANIC CARBON (TOC) ANALYZER:

-

-

Principle of Total Organic Carbon (TOC) Analyzer:

-

-

- Total Organic Carbon (TOC) Analyzer converts the carbon in the sample to CO2.

-

- The NDIR uses electromagnetic radiation or infrared energy to measure this CO2.

-

- This measurement is proportional to the carbon in the sample.

-

- Carbon dioxide shows a unique adsorption spectrum when IR energy passes through it.

-

-

Precautions during analysis of Total Organic Carbon (TOC):

-

-

- For best results, change rinsing water daily and store prepared reagents away from direct sunlight.

-

- Use the sucrose and 1,4 Benzoquinone USP reference standard and store the same as per recommend storage condition.

Related: Cleaning of Laboratory Glassware

-

- Use A-grade glassware for sample collection.

-

- In any case don’t rinse the glassware used for Total Organic Carbon (TOC) analysis with any solvent.

-

- Glassware required for Total Organic Carbon (TOC) analysis should be cleaned for organic residue, rising with 2N nitric acid then with purified water 3-4 times and dry the TOC sampling container’s for 105°C for 30 min.

-

- Preferably such glassware should be maintained separately and to be dedicated for Total Organic Carbon (TOC) analysis.

-

- At the sample, collection point rinses glassware with sample water 3-4 times.

-

- The sample should be analyzed immediately after it is brought to the lab.

-

-

Sampling procedure for the test of Total Organic Carbon (TOC):

-

-

- Carry the sampling container (s) and other required accessories to the sampling point in a tray.

-

- During sampling wear the face mask and hand gloves.

-

- Open the valve of user point and allow the water to flush for at least 30 seconds.

-

- Open the sampling container near to the mouth of sampling point and rinse the container with the water to be sampled.

-

- During sampling don’t touch the mouth of sampling container and user point.

-

- Carefully fill the water sample up to brim.

-

- Close the sampling container with glass stopper quickly, ensuring that no air gap remains in the container.

-

- Close the valve and mouth of user point.

-

- Bring the sample in the quality control laboratory for analysis.

-

-

Preliminary check of Total Organic Carbon (TOC) Analyzer:

-

-

- Check that the instrument and it’s surrounding are clean, if not clean with a soft cloth duster.

-

- Ensure that the system is connected to a stabilized power supply and the zero air cylinder.

-

- Check the levels of dilution water, acid, drain vessel water and humidifier water each day before starting the instrument and adjust the volume if required with the respective reagent / solution.

-

- Preparation of sample:

-

- Put the sample tubing in the sample and cover with parafilm properly.

-

-

Operation of TOC:

-

-

- Switch on the Computer & Total Organic Carbon (TOC) Instrument.

-

- Double Click on TOC-V Table Editor Icon on desktop.

-

- Enter Password then click Ok, window will open.

-

- Go to Tool Bar, click on “New”. Select H/W Setting window will displayed. Click on Ok

-

- Sample Table-TOC-VCPH window will open.

-

- Click on Insert Menu and select Multiple Samples.

-

- Sample Group Wizard (page 1) Sample Source window will be displayed. In this page

-

- Select the calibration curve. Now browse calibration curves by selecting Browse button.

-

- Calibration Curve Files list window will open, In this calibration file list select the recent calibration file and then click on open.

-

-

Now click on Next in the page 1.

-

-

- Sample Group Wizard (page 2) Sample Parameters window will displayed.

-

- In this page enter the Number of samples, give the Sample Name and Sample ID then click on Index Start.

-

- Now click on Finish in page 2

-

- Enter the Sample ID to be analyzed.

-

- Now click on the Connect button on Tool Bar.

-

- The sequence window will open.

-

- The instrument will start Initializing.

-

- The initialization window will disappear when 100% initialization is completed.

-

- Now, pressure Gauge should show 6 Kg/cm² (200 Kpa) and flow meter should be 150 ml/min.

-

- Click on the Monitor button on Tool Bar, Background Monitor window will open.

-

- Wait for 15 to 20 min for getting the instrument ready condition (see background conditions like Furnace Temp., Dehumidifier Temp., Baseline Position, Baseline Fluctuation, Baseline Noise)

-

- When all the lines turns red to green, close the Background Monitor window.

-

- Go to Instrument Menu and click on Maintenance then select Residue Removal, click on start. click on close after completion.

-

- Go to Instrument Menu and click on Maintenance then select Washing, Washing window will displayed, click on Select Flowline, Wash Flow Line window will be displayed.

-

- Select TC port, IC port OFF lines then click on washing to start the washing.

-

- Close the window when washing is completed.

-

- Now click on Start from the Tool Bar, Save as Window will open, click on save Means mode window will open. Select the Normal and click on Ok.

-

- Total Organic Carbon (TOC) Measurement window will be displayed and then click on start.

-

- Either SD or CV area should be in limit.

-

-

System Suitability Test of Total Organic Carbon (TOC) Analyzer:

-

-

- System suitability is performed as per USP specifications. USP reference standards Sucrose and 1,4-Benzoquinone are used as standards.

-

- First, calibrate the Instrument after setting the water as Zero ppb (0 ppb) and Sucrose (500ppb).

-

- Select “New” from the File Menu. Then Click on “Calibration Curve ”

-

- Calibration Curve Wizard (Page 1) System Information window will be displayed, in this page select the System as TOC-VCPH and click on Next.

-

- Calibration Curve Wizard (Page 2) Calibration Curve Type window will be displayed,

-

- On this page select the Calibration according to USP/EP and click on Next.

-

- Calibration Curve Wizard (Page 3) Analysis Information window will be displayed, in this page select the analysis as NPOC and give the Sample Name(Blank+ Sucrose) and Sample ID (Calibration Curve) also give the File Name for this Calibration Curve template, and then click on Next.

-

- Calibration Curve Wizard (Page 4) Calibration Measurement Parameters window will be displayed, In this page see all the Injection parameters are OK. If not, select them and click Next.

-

-

The specified parameters are:

-

-

-

- Units ppb

- Number of injections 3-8

- SD 0.5000

- CV 3.0

- Number of washes 2.0

- Sparge time 0:30 min.

- Acid addition 0.5

-

-

- Calibration Curve Wizard (Page 5) Calibration Points Lists window will be displayed, In this page Click on Edit and set the Calibration Point Concentration (500 ppb) for Sucrose then click on ok, again click on Next.

-

- In the Calibration Curve Wizard (Page 6) Additional Settings, Click on Finish.

-

- After creating the calibration file, Select “New” from the File Menu. Then Click on “Control Sample”.

-

- Control Sample Wizard (Page 1) System Information window will be displayed, in this page select the System as TOC-VCPH and click on “Next”.

-

- Control Sample Type window will be displayed In this Page select the “System Suitability Test for USP/EP” also give the File Name for this Control sample template, and then click on “Next”.

-

- Control Sample Wizard (Page 3) Parameters Sources window will be displayed, In this page Select the “Calibration Curve” and Browse for the calibration curve. Select the cal curve and click on “Open”. Click on “Next”.

-

- Control Sample Wizard (Page 4) Analysis Parameters window will be displayed, In this page select the Analysis as NPOC, give Sample Name (1,4-Benzoquinone) and sample ID (System Suitability) and then click on Next”.

-

- Control Sample Wizard (Page 5) Injection Parameters window will be displayed In this Page see all the Injection parameters are Ok. If not, select them and click Next.

-

-

In Control Sample Wizard (Page 6) Peak Time Parameters, click on “Next”.

-

-

- In Control Sample Wizard (Page 7) Control Checking, Click on “Finish”.

-

- Now we have to insert the “Calibration Curve and Control Sample” in table row.

-

- On the Sample, Table place the cursor in the row where the Calibration Curve will be inserted.

-

- From the Insert, Menu select Calibration Curve, and the File Name dialog box will be displayed, select the file name and click on Open. Again go to Insert Menu select Control Sample, and the File Name dialog box will be displayed, select the File Name and click on Open.

-

- Now the Calibration Curve and Control Sample will be inserted in the sample table row.

-

- Now Click on “START” from the Tool Bar. Save as Window will be displayed now click on save then Means mode Window will be Displayed, Select the normal button and click on OK.

-

- Total Organic Carbon (TOC) Measurement Window will be displayed, click for start.

-

- The instrument will analyze the sample and it will give results automatically.

-

- Observe the results for the calibration curve and system suitability as per the above procedure.

-

- The % recovery of system suitability should be between 85% to 115%.

-

- Frequency of system suitability: weekly

-

- Maintenance Checks: The following components should be checked

-

-

- Carrier gas pressure 6 kg/cm² (200kPa).

-

-

-

- Carrier gas flow rate of 150ml/min.

-

-

-

Reagent Preparation:

-

-

- To prepare KHP

-

- Weigh 212.5 mg of KHP, add it to a 100ml volumetric flask and make up the volume 100ml with purified water.

-

- Take 1 ml of 1000ppm solution of KHP in a 100ml volumetric flask and make up the volume 100ml with pure water. This will give a 10ppm solution of KHP.

7.0 PROCEDURE CALIBRATION OF TOTAL ORGANIC CARBON (TOC) ANALYZER:

-

-

Four Point Calibration of Total Organic Carbon (TOC) Analyzer:

-

-

- Set the MQ water as zero ppb and prepare 250ppb, 500 ppb and 1000ppb solutions of KHP in MQ water.

-

- Do the 4 point calibration by selecting dilution from standard solution.

-

- Prepare a calibration curve using the above standards and blank as per the above-explained calibration procedure.

-

- The correlation coefficient (r2) must be greater than 0.980

-

- Frequency of calibration: Monthly

-

-

To prepare the Sucrose solution:

-

-

- Dry the USP reference standard Sucrose at 1050C for 60-90 minutes in a hot air oven and cool to room temperature.

-

- Weigh accurately 11.9mg of this sucrose and dissolve it in 100 ml volumetric flask.

-

- Make up the volume 100ml with pure this gives 50 ppm sucrose solution.

-

- Use this solution as a mother solution.

-

- Take 1ml of this solution in a 100ml volumetric flask and make up the volume 100ml.

-

- This gives a 500ppb solution of sucrose.

-

-

To prepare 1,4 Benzoquinone solution:

-

-

- Weigh 7.5mg of 1,4 Benzoquinone and add it to a 100ml volumetric flask.

-

- Make up the volume 100ml with pure water. This gives 50ppm Benzoquinone solution.

-

- Take 1 ml of this solution in a 100ml volumetric flask and make up the volume 100ml.

-

- This gives a 500ppb solution of 1,4 Benzoquinone.

-

- Limit: The Total Organic Carbon of purified water must not be more than 500ppb

8.0 ANNEXURES – SOP OF TOTAL ORGANIC CARBON (TOC) ANALYZER :

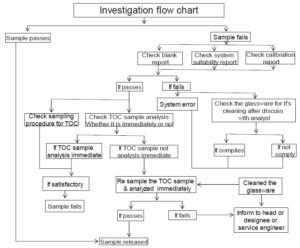

Annexure- 1: Investigation flow chart of Total Organic Carbon (TOC) failure result.

Annexure- 2 : Calibration Record of Total Organic Carbon (TOC).

Checking of Linearity using Potassium Hydrogen Phthalate

| Instrument Name | TOC | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Quarterly ± 7 days | |

| Calibration date | Next Calibration due on |

| Reagent | Batch No. | Make / Grade | Use Before |

| Potassium Hydrogen Phthalate | |||

| Water | NA |

- Reagent Preparation:

-

- To prepare KHP

-

-

- Weigh _______ 212.5mg of KHP, add it to a 100ml volumetric flask and make upthe volume _____ 100ml with ______ water (DM water).

-

-

-

- Take _____ ml (1ml ) stock of KHP in a 100ml volumetric flask and make up the volume _____ ml (100ml) with pure water. This will give a 10ppm solution.

-

-

-

- Prepare a 4 point calibration method in the instrument for the following concentration using the auto dilution procedure, Conc. 0, 250, 500 and 1000ppb

-

-

-

- Record the correlation coefficient ( r2) value for the linearity curve.

-

-

- Limit – NLT 0.980

- Observation :……………………………………………………………………………

- Correlation Co – efficient = ____________

Remark :The instrument is calibrated & qualified / Out of calibration & not qualified for use.

| Calibration : Scheduled / Not scheduled ( Reason : _________________________________ ) |

Calibrated By: Checked By Approved By:

Annexure- 3: Total Organic Carbon (TOC) Checklist for sample failure in the analysis.

| Sampling date: | |

| Sample ID: |

| S. No. | Check point |

| 1. | Is water blank report |

| 2. | Is system suitability complies as report |

| 3. | Calibration report |

| 4. | System monitoring |

| 5. | Is TOC sample analysis immediately |

| 6. | Is glassware cleaned where ever required for sampling and analysis |

| 7. | TOC sampling procedure (Discuss with analyst) |

| 8. | Review the sampling procedure |

| 9. | Resampling of TOC sample( If required) |

| Remarks by investigator :

|

|||

| Prepared By: | Checked By: | ||

| Sign./Date | Sign./Date | ||

Pingback: Quality Monitoring of Water (Raw & Portable) - Pharma Beginners