Control Sample is an appropriately identified reserve samples that is representative of each batch, in the same container closer system in which the product is marketed. It may Starting Material, Packaging Material, Drug Substance or Finished Drug Product which is stored to evaluate the potential risk during self life of the batch.

Control Sample is an appropriately identified reserve samples that is representative of each batch, in the same container closer system in which the product is marketed. It may Starting Material, Packaging Material, Drug Substance or Finished Drug Product which is stored to evaluate the potential risk during self life of the batch.

Sample should be stored in simulated packaging as product marketed.

Standard Operating Procedure for Control Sample Collection, Storage, Monitoring and Evaluation.

SOP for Control Sample Management

1.0 PURPOSE:

To lay down procedure for handling of control samples.

2.0 SCOPE:

This procedure is applicable to all finished marketed products manufactured at location.

3.0 REFERENCES:

-

- In House

-

- Preparation, review and control of standard operating procedure.

-

- Event Reporting and Investigation SOP.

-

- SOP for Monitoring of temperature and relative humidity and pressure difference

4.0 RESPONSIBILITY:

-

- QA shall responsible for Collection, storage, periodic inspection, destruction and maintain the records of control sample as per the lay down procedure.

-

- QA Head shall responsible for review and ensure that the procedure has been performed.

-

- Plant Head and Head-Quality shall be responsible for approval of SOP.

5.0 ABBREVIATIONS:

-

- CGHS : Central Government Hospital Supply

-

- CSR No. : Control Sample Receipt Number

-

- ETP : Effluent Treatment Plant

-

- EHS : Environment Health and safety

-

- OOS : Out of specification

-

- PS. : Physician Sample

-

- QA : Quality Assurance

-

- SOP : Standard Operating Procedure

6.0 PROCEDURE:

-

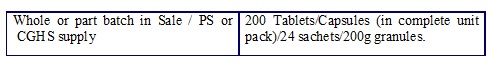

Sample Quantity:

- Quantity of sample collected should be sufficient to carry out at least two complete analysis, except microbial analysis.

-

- Collect the samples as per below .

-

Collection :

- Collect the Control sample from each batch of all marketed finished product.

-

- Trained personnel of QA shall withdraw the control samples during packing at regular intervals of initial, middle and end of the packing cycle.

-

- QA shall enter the withdrawn quantity of control samples in to the respective batch packing record.

-

- Collect the samples in fully packaged units and stored in a secondary packing.

-

- Put the stamp of “CONTROL SAMPLE” on the show box or on the outer pack in black ink along with sign and date.

-

- Keep the samples under lock and key provision by QA to avoid any misplacement, prior storage in to the control sample room.

-

- The sample shall store in the same immediate container closure system in which the finished drug product marketed.

-

- Where samples of finished drug product are packed in large bulk containers, a small quantity of finished drug product can be retained in a similar container closure system in which the finished drug product is marketed.

-

- Enter the product details in log (Annexure-1)

-

Storage :

- Store the samples in secured Control Sample room in as such condition .

-

- QA shall assign the location number of sample on right top side of the shipper which shall represent the receipt number of control sample along with room and rack number.

-

- Assign the location as per “RM00/RK00/SP00/XXXX” procedure

RM01/RK01/SP01/0001

Where,

-

-

- RM01 : denote the room No.01,

-

-

-

- RK01 : the rack No.01 of the room,

-

-

-

- SP01 : the shipper no. of rack and

-

-

-

- 0001 indicates the receipt no. of sample

-

-

- Temperature of the control sample room should not be exceed to 27°C.

-

- Perform the environmental condition of sample room once a day as per respective sop for Monitoring of temperature and relative humidity and pressure difference.

-

- Retain the samples for one year after the date of expiry of the product.

-

- Restrict the entry in the control sample room as per Annexure-2 (List of authorized person).

-

- Entry of Un-authorized person shall allowed with the authorized person.

-

Issuance & Visual Inspection:

- Issue the samples for for inspection when required for the purpose of market complaint or event investigation, OOS observation etc. after approval from QA head.

-

- Sample shall issue to concerned person on receipt of approved Sample Request and issuance log book (Annexure-3)

-

- Record the quantity of issued sample quantity on the show box of respective Control sample along with request number.

-

- Request numbering system shall in pattern of “CSR No.-YY/XX/0001”

Where,

-

-

- CSR No. indicates the control sample receipt no.,

-

-

-

- YY indicates the current year,

-

-

-

- XX denote to current month,

-

-

-

- 0001 indicates the serial number of request.

-

-

- Concerned person shall check the physical condition of control sample and maintain the Annexure-3 (Control Sample Request and issuance log book)

-

- If balance quantity of issued control sample shall return to QA ,

-

- Record the details in sample request and issuance log book (Annexure-3)

-

Periodic Inspection :

- Every 10th batch of each finished product meeting the inspection criteria shall be selected for physical inspection.

-

- If during the year less than 10 batches are manufactured than any one batch shall be considered for the physical verification.

-

- The sample of that batch shall be inspected physically every year (±30 days) till expiry date.

-

- QA shall prepare the control sample list due for physical inspection per month and shall approve the request prior to inspection as per Annexure-4.

-

- Take one strip from selected batch for periodic physical inspection.

-

- Physical inspection of dosages unit and primary packaging components shall be carried as per reference Annexure-5 and should be recorded in monthly periodic inspection record (Annexure-6)

Note.: If the primary packaging components and dosage are in good condition, inspector shall enter “√” or in non satisfactory case shall enter “X” mark in the observation column.

-

- Handle all non confirmatory observations through event investigation. (refer respective sop for handling of Event Investigation).

-

Destruction :

- Destroy the samples after one year of product expiry.

-

- QA shall prepare the list of samples for destruction as per Annexure-7 (Control sample disposal authorization form) and record in log book (Annexure-1) per month.

-

- Authorization of Head QA required for sample destruction.

-

- Segregate all the strips from leaflets, show boxes and other paper materials.

-

- De-foil the strips/blister manually.

-

- Shred the paper material and foils manually or shredded.

-

- Store the de-foiled samples in waste material bag affix with status label Annexure-8

-

- It shall be send to EHS department for disposal.

Pingback: Out of Specification Result in Microbiology - Guideline - Pharma Beginners

Pingback: Stability Study SOP as per ICH Guideline - Pharma Beginners

Pingback: SOP for Drug Product Recall & Mock Recall - Pharma Beginners