Standard Operating Procedure (SOP) for Operation, Cleaning, and Calibration of Micro & Semi-Micro Analytical Balance used for weighing WS & Impurities in QC and Research Laboratories.

Procedure for Micro Balance Operation and Calibration

1.0 PURPOSE:

-

- To describe the procedure for operation, calibration, and performance check of the Micro Balance.

2.0 SCOPE:

-

- The SOP applies to the Mettler Toledo make the Micro Balance (for Operation part – Model XS205) and Calibration of All types of Micro and Semi-Micro Balances used in the Quality Control department.

3.0 REFERENCES:

-

- Instrument Operation Manual

-

- USP General Chapters <41> Weights and balances

-

- USP General Chapter <1251> Weighing on an analytical balance

-

- 21 CFR 211.68: Automatic, mechanical and electronic equipment

-

- Indian Pharmacopoeia (2.1.7. Weights and balances)

-

- Maintenance of laboratory instruments – SOP

-

- Instrument/Equipment usage logbook – SOP

-

- Preparation of internal and external (Third Party) calibration schedule and calibration practices – SOP

-

- URS and Analytical Instrument/ Equipment Qualification – SOP

-

- Handling of out of calibration – SOP

4.0 RESPONSIBILITY:

-

-

QC Personnel shall be responsible for:

-

-

- Operate the instrument as per the SOP.

-

- Carry out the calibration of the Micro Balance as per the SOP.

-

- Keep all records related to calibration and to perform proper documentation as per the SOP.

-

-

Quality Control Head or Designee shall be responsible for:

-

-

- Check the SOP.

-

- Ensure proper documentation as per the SOP.

-

- Provide training to the concerned persons before the implementation of the SOP.

-

- Ensure that the Micro Balance is operated and calibrated as per the SOP.

-

- Initiate the maintenance activity during the breakdown of the instrument.

-

- To investigate out of calibration (if any).

-

-

Quality Assurance Head shall be responsible for :

-

-

- Review and Approval of the SOP.

-

- Ensure the implementation of the system as per the SOP.

5.0 ABBREVIATIONS USED IN SOP FOR MICRO BALANCE:

-

- CFR: Code of Federal Regulations

-

- FACT: Fully Automatic Calibration Technology

-

- IPA: Iso Propyl Alcohol

-

- IQ: Installation Qualification

-

- NIST: National Institute of Standard and Technology

-

- OQ: Operational Qualification

-

- PQ: Performance Qualification

-

- QA: Quality Assurance

-

- QC: Quality Control

-

- SOP: Standard Operating Procedure

-

- URS: User Requirement Specification

-

- USP: United States Pharmacopoeia

-

-

DEFINITION OF WORDS USED IN THE SOP FOR MICRO BALANCE:

-

-

- Hysteresis:

-

- The delay between the action and reaction of a measuring instrument.

-

- Hysteresis is the amount of error that results when this action occurs.

-

- Note: Hysteresis in the Micro Balance is caused by excessive stretching of the springs, and it is primarily due to overloading or to the accidental dropping of an object onto the pan.

-

- Accuracy :

-

- A qualitative concept that defines the extent to which the weight readouts of a scale approaching the true value of the quantities weighed.

-

- Linearity :

-

- For weighing instruments, linearity means the positive or negative deviation of the readout from the actual load.

-

- It is the amount of deviation from an instrument ideal straight-line performance.

-

- Sensitivity:

-

- Change in the displayed value divided by the load on the weighing instrument, which causes this change.

-

- Repeatability:

-

- The ability of a weighing instrument to display corresponding results under constant testing conditions, when the same load is repeatedly placed onto the weighing pan in the same manner.

-

- Eccentricity:

-

- Also referred to as “corner load error” or “off-center loading error”.

-

- This is the change in readout when the same object is placed in various positions on the weighing pan.

6.0 PROCEDURE FOR MICRO BALANCE OPERATION AND CLEANING:

-

General Procedure:

-

- Follow the SOP on Instrument/Equipment usage logbook, for the entry of usage of the Instrument/Equipment.

-

- In case of any maintenance of the instrument, follow SOP on Maintenance of Laboratory Instrument.

-

- Maintain the third party calibration schedule and the Internal calibration schedule for the instrument as per SOP on the Preparation of internal and external (Third Party) Calibration schedule and calibration practices.

-

- For IQ/OQ/PQ and re-qualification follow the SOP of URS and Analytical Instrument/ Equipment Qualification.

-

- In case of failure of calibration follow the SOP of Handling of out of calibration.

-

Precautions during handling of Micro Balance:

-

- The Micro Balance should be kept on a firm and vibration-free surface.

-

- Air currents should not present near the Micro Balance.

-

- The Micro Balance should be installed in a temperature and humidity controlled room.

-

- The balance door should not be open during weighing.

-

- The Micro balance should not be installed near the source of electromagnetic radiation or magnetic field.

-

- Ensure that the temperature of the Micro Balance and material to be weighed are the same.

-

- Hygroscopic material should not be exposed for a longer time in the air during weighing.

-

- Hysteresis of the mechanical parts should not occur.

-

- Place the weight in the center of the microbalance pan to eliminate the corner-weighing difference.

-

- Do not overload the Micro Balance pan more than the capacity of the balance.

-

- Many chemicals, such as salts are corrosive, and material of this nature should not be spilled on the Micro Balance pan or inside the balance housing.

-

- Before weighing or calibration, the Micro Balance should be exactly in a horizontal position (check the level indicator, which should be in the center).

-

- If any unevenness is observed in its location, it should be corrected by turning leveling feet until the level bubble is in the center of the indicator.

-

General information about the Micro Balance :

-

- Always use a calibrated weight box for calibration purposes.

-

- The weight class chosen for the calibration should be such that the tolerance of the weights used does not exceed 0.1% of the amount weighed.

-

- The weights used for calibration shall be calibrated against standard weights traceable to NIST.

-

- The weight box shall be calibrated by the standard lab before its validity expires.

-

- The weight box shall be calibrated by outside agency yearly ± 30 days.

-

- The analyst shall sign the print out with the date and paste it in the calibration logbook.

-

- After calibration analyst shall submit the raw data for checking.

-

- The analyst shall update the calibration status label and make an entry in the instrument usage logbook of the Micro Balance.

-

-

Calibration of Weight Box :

-

-

- After the receipt of the calibrated weight box along with the calibration certificate limit for allowable tolerance limit (for external calibration) should be calculated as minimum and maximum weight from the limit in terms of % mentioned in Attachment-1 for all the weight which is required for the calibration.

-

- For e.g.: The actual mass value found after calibration is 200.0050 gm, then 199.8050 gm to 200.2050 gm is the minimum and maximum weight limit as per ±0.1% of the actual mass value.

-

- The calibration templates i.e Attachments -1 and Attachment -2 shall be filled for the details like minimum and maximum weight limits (as calculated above) against their actual weight for the weights mentioned in the template.

-

- The template shall be verified by the designed person.

-

- A scanned copy of the attachments shall be maintained which shall be reprinted and issued each time the calibration is done.

-

- After calibration, the raw data shall be submitted for checking.

-

- The analyst shall update the calibration status label and make an entry in the instrument usage log book.

-

- If the weight print facility of Micro Balance is not working, then inform to service engineer for rectification of this problem.

-

- Till rectification of the problem, weight during weighing will be checked and signed by the section head or designee.

-

- If the print facility is available then attach the printouts with the template.

-

Cleaning Procedure of Micro Balance:

-

- Remove powder if any, from inside the Micro Balance using a soft nylon brush & wipe with clean cotton balls.

-

- Remove weighing pan & wipe it with a soft nylon brush, if required, wipe with clean cotton soaked in 70 % IPA solution & dry the pan with cotton balls completely before mounting.

-

- Wipe carefully the inner side of the Micro Balance with clean moist cotton with 70% IPA solution in water without disturbing the balance & finally mop with clean dry cotton.

-

- In case of dirty spots or stains on the body, use cotton balls soaked in 70 % IPA solution in water.

-

Operation Procedure of Micro Balance:

-

- The Micro Balance should be placed in a suitable location with sufficiently low levels of vibration, air current, and with the constant electrical supply.

-

- The Micro Balance and surrounding work area have to be kept neat and tidy.

-

- Connect the AC adapter supplied to the connection socket of the evaluation unit and then to the power supply.

-

- Ensure that Micro Balance is clean and horizontally leveled (Bubble should be in the center of the leveling control).

-

- If any minor unevenness in its location is observed, then adjust the level by turning two leveling feet at the rear of the balance until the air bubble comes within the center of the leveling control.

-

- The illuminated graphic display of the terminal is a “Touch screen”.

-

- The screen shows different function keys that can be activated by touching that particular part of the screen.

-

- Key “1” returns the screen from any menu level back to the active application any changes made up to the point is are automatically saved.

-

- Second Key “2” allows choosing different applications such as normal weighing, statistics, formula weighing, and density determination.

-

- Key “3” allows changing the settings of the instrument.

-

- Key “4” transmits the weighing result over the interface, e.g. to a printer.

-

- “Adjust.int” key allows adjustment of the Micro Balance using an internal adjustment weight,

-

- Use this function after switching on the Micro Balance and allow the balance to equilibrate for an hour and then use the balance for weighing.

-

-

Note:

-

-

- The Micro Balance is equipped with FACT, it adjusts and linearizes the balance automatically with specified temperature criteria.

-

- As soon as the specified temperature criteria are reached, the small FACT icon appears in the top right-hand corner of the display and the balance starts the process.

-

- If it occurs during the weighing process it can be canceled with the cancel button.

-

- The balance will carry out the adjustment in the next opportunity.

-

- The “Display” key allows switching between different types of display, the factory setting of the Micro Balance displays the weighing result at a size so that it can be easily read.

-

- The other type of display shows the information field and “SmartTrac” which is a graphical display, which shows at a glance, the weighing range that has already been filled and the range that is still available.

-

- 1/10d” key allows modifying the readability of the weighing result at any stage of the work.

-

- It displays the result with only one-tenth of the precision, i.e. with one less decimal point.

-

- Calibrate the Micro Balance as per the given calibration procedure.

-

- If the Micro Balance show “————-” display, it means balance is busy.

-

- After the symbol disappears, press the “>0<” key to get zero on display.

-

- Clean the weighing pan and close the draft shield.

-

- After the unstable mark disappears ‘O’, press TARE key >T< and the display shall be “0.0000 mg”.

-

- Then open the draft shield for weighing.

-

Weighing Procedure on Micro Balance:

-

- Butter paper/receiver of appropriate size with respect to the quantity of sample shall be taken.

-

- The desired quantity of the sample shall be added slowly to the center of the butter paper /receiver.

-

- The weight taken should be ± 10% of the specified weight or as specified in the individual monograph.

-

-

Addition weighing:

-

-

- Additional weighing is used for solid samples or liquid samples for which volatility is not an issue.

-

-

- Place the empty butter paper / or receiver on the microbalance in the center of the pan, and press the appropriate tare (Zero) key on the balance (On stabilization of indicator).

-

-

-

- Add the desired amount of material to the butter paper / or receiver, and allow the balance to display stabilize reading (On stabilization of indicator).

-

-

-

- Record the weight and transfer the weighed material to the final flask or beaker as per requirements, then reweigh the original weighing butter paper / or receiver by placing it in the same position on the pan

-

-

-

- Note- Do not change the set tare of the balance between these two weighings.

-

-

-

- The difference between the two weights represents the transferred material weight.

-

-

-

Dispense weighing:

-

-

-

- Dispense weighing is used for weighing of emulsions or viscous liquids such as ointments.

-

-

-

- Tare the Micro Balance (On stabilization of indicator), place the sample container on the balance in the center of the pan in a suitable container (bottle, tube, transfer pipette, or syringe) and record the weight (On stabilization of final flask or beaker as per requirements, then reweigh the sample container by placing back on the pan of balance [ Note- Do not change the set tare of the balance between these two weightings].

-

-

-

- The difference between the two weights represents the transferred material weight.

-

-

-

Liquid and volatile material weighing:

-

-

-

- Weighing of liquid and/ or volatile material (which has a low boiling point) shall be done as per the procedure defined below.

-

-

-

- Place the empty receiver (In case of material is highly volatile, add some amount of diluent) on the Micro Balance in the center of the pan and press the appropriate tare (Zero) key on the Micro Balance (On stabilization of indicator).

-

-

-

- Check the outer edge and the bottom of the receiver.

-

-

-

- It should be clean and dry.

-

-

-

- Add the desired amount of material to the receiver with the help of a clean and dry pipette or capillary tube.

-

-

-

- On stabilization of the indicator displayed weight will be transferred material, which shall be printed and kept with the raw data.

-

-

-

Hygroscopic samples:

-

-

-

- Hygroscopic material readily absorbs moisture from the atmosphere and steadily gains weight.

-

-

-

- Therefore hygroscopic samples shall be either weighed promptly or placed in a vessel with gas-tight closure.

-

-

-

- For a gas-tight vessel, the analyst shall tare the vessel and enclosure, add the desired amount of sample in the vessel and replace the enclosure and record the weight.

-

-

-

- The difference between the two weights represents the transferred material weight.

-

-

-

Viscous liquid material weighing :

-

-

-

- Place the empty receiver on the Micro Balance in the center of the pan and press the appropriate tare (Zero) key on the Micro Balance (On stabilization of indicator).

-

-

-

- Add the material to the receiver, slowly so that the maximum required volume can be transferred to the vessel. On stabilization of the indicator, the displayed weight will be the transferred material, which shall be printed and kept with the raw data.

-

-

-

Semi-solid material weighing :

-

-

-

- Place the empty receiver on the Micro Balance in the center of the pan and press the appropriate tare (Zero) key on the Micro Balance (On stabilization of indicator).

-

-

-

- Transfer the approximate required quantity of semi-solid material to the receiver (by touching the inner surface of the receiver) with the help of a capillary tube or spatula.

-

-

-

- On stabilization of the indicator displayed weight transfer material,

-

OR

-

-

- Place the clean and dry glass coverslip on the Micro Balance in the center of the pan and press the appropriate tare (Zero) key on the balance (On stabilization of indicator).

-

-

-

- Transfer approximate required quantity of semi-solid material to the glass coverslip with the help of a capillary tube or spatula.

-

-

-

- On stabilization of the indicator record the displayed weight and transfer the glass coverslip directly into the receiver.

-

-

-

Warm or cool samples:

-

-

-

- The sample that is warm or cool shall be equilibrated in the laboratory to room temperature because if warm samples are weighed then the apparent weight is smaller than the true weight because of heat convention.

-

-

- Aseptic or bio-hazardous materials weighing:

-

-

- The weighing of the sterile or bio-hazardous samples shall be done within the confines of a clean bench, bio-safety cabinet, isolator, or similar containment device.

-

-

-

- Airflow within the hood potentially can cause Micro Balance instability, so after a Micro Balance has been installed under the hood, perform a rigorous qualification study with suitable weight in order to determine the acceptability of the Microbalance performance in this environment.

-

-

- Corrosive materials weighing:

-

-

- Many chemicals, such as salts are corrosive, and material of this nature should not be spilled on the balance pan or inside the Micro Balance housing.

-

-

-

- Extra care shall be taken when the material of such nature are weighed.

-

-

-

- In the event of a spill re-qualification of Micro Balance may be required, depending on the nature of the spill.

-

-

Calibration Parameter and Frequency of Micro Balance:

-

- Internal Adjustment: It shall be performed on every working day, after a power failure, after any maintenance and relocation of the Micro Balance.

-

- Linearity: It shall be performed on every working day, after a power failure, after any maintenance and relocation of the Micro Balance.

-

- Sensitivity: It shall be performed monthly, after any maintenance and relocation of the Micro Balance.

-

- Repeatability (Uncertainty): It shall be performed monthly, after any maintenance and relocation of the Micro Balance.

-

- Accuracy: It shall be performed monthly, after any maintenance and relocation of the Micro Balance.

-

- Eccentricity: It shall be performed monthly, after any maintenance and relocation of Micro Balance.

-

Calibration Procedure of Micro Balance :

-

-

Auto Calibration check (Internal Adjustment):

-

-

- Calibration frequency: Daily (except holidays) and after any maintenance.

-

- Ensure that the weighing pan is clean and close the door of the weighing chamber.

-

- First, carry out a level indicator check of the bubble.

-

- If the bubble is not in the center set it as per the procedure.

-

- Turn the leveling feet until the air bubble is centered exactly within the circle of level indicator.

-

- Press the “Adjust.int” key to start the internal calibration.

-

- If the process completes successfully the display shows

” INTERNAL ADJUSTMENT”

Temperature XX.X °C

Where ‘X’ is a numerical variable.

-

- If the calibration is not successful, the display will show an appropriate message indicating that the calibration process is aborted as a result of an error.

-

- Press the OK key to escape.

-

- Linearity:

-

- Carryout the Linearity by using 100 mg, 1.0 gm, and 5.0 gm weights.

-

- Put the weight of 100 mg, 1.0 gm, and 5.0 gm on the pan and record the weight in Attachment-1.

-

- Deviation NMT +05% of the actual mass value.

-

-

Sensitivity:

-

-

- Carryout the Sensitivity by using 200 gm weights.

-

- Put the weight of 200 gm on the pan and note the measurement in the template (Attachment-2).

-

- Deviation NMT +05% of the actual mass value.

-

-

Repeatability (Uncertainty):

-

-

- The Repeatability shall be carried out by using 100 mg and 100 gm weight.

-

- Put the external weight of 100 mg on the pan and note the 10 measurements in Attachment – 2

-

- Calculate the measurement of Repeatability as follows.

Standard deviation x 2

Repeatability = ——————————————————————————————-

The nominal value of the weight used for the desired smallest net weight.

Note: In case the calculated standard deviation of 10 replicate measurements is smaller than 0.41d value then replace the standard deviation value with 0.41d value. Where “d” is the scale interval (readability) of Micro Balance.

-

- Replace the external weight of 100 mg with 100 gm and note the 10 measurements in the Attachment –2

-

- Repeatability shall not be more than 0.0010 or 0.10%.

-

- Accuracy check :

-

- Carry out Accuracy check by using 10 gm, 100 gm, and 200 gm weights

-

- Deviation NMT 0.10% of the actual mass value.

-

-

Eccentricity:

-

-

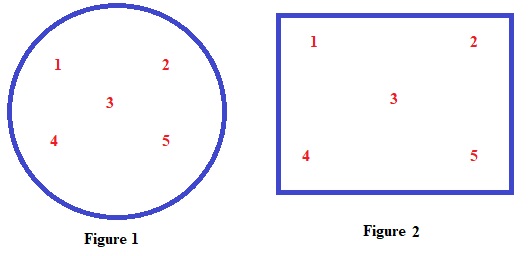

- Take the 100 gm weight and weigh 5 times on different places of the pan as shown in figure-1 (when the microbalance pan is circular) and figure-2 (When the microbalance pan is square) and record the observation in the Template for Corner test (Attachment-2).

-

- Every five readings should lie in the range of ± 0.05% of the actual mass value of weight.

7.0 ANNEXURES – MICRO BALANCE CALIBRATION:

Annexure-1: Daily Calibration Template.

- Internal adjustment

| Instrument Name | |||

| Instrument Code | Make /Model | ||

| Location | Calibration frequency | ||

| Calibration date | Next calibration due on | ||

| Weight Box No. | Valid up to | ||

-

- Check level indicator (Bubble should be in center)_______________________

-

- Paste internal adjustment check printout here__________________________

- Linearity check log

| Date

|

Level indicator check

|

Actual mass value (100 mg)=

|

Act. mass value (1.0 gm)=

|

Actual mass value (5.0 gm)

|

Weight box No. & Valid up to

|

Done by

|

Checked by | Remark |

| Limit Þ | Bubble should be in Center

|

Limit:(± 0.05%of actual mass)

_________mg to _________mg |

Limit:(± 0.05%of actual mass)

________gm to ________gm |

Limit:(± 0.05%of actual mass)

________gm to ________gm

|

||||

- Remarks: The Calibration of the instrument found satisfactory / Not satisfactory.

Annexure-2: Monthly Calibration Template.

- Sensitivity check :

| Instrument Name | ||||||||||

| Instrument Code | Make / Model | |||||||||

| Location | Calibration frequency | |||||||||

| Calibration date | Next Calibration due on | |||||||||

| Weight Box Code No. | Valid up to | |||||||||

| Date

|

Level indicator check

Actual mass value of 200 gm weight= |

Weight box No. & Valid up to

|

Done by

|

Checked by

|

Remark

|

|||||

| Limit Þ

|

Bubble should be in Center

Limit:+0.05% of actual mass value |

|||||||||

- Remarks: The Calibration of the instrument found satisfactory / Not satisfactory.

- Accuracy :

| Date

|

Level indicator check

|

Actual mass value 10gm= ±0.10% of actual mass value

|

Actual mass value 100 gm=

±0.10% of actual mass value

|

Actual mass value 200 gm=

±0.10% of actual mass value

|

||||

| Limit Þ

|

Bubble should be in Center

|

Limit: ___________ gm

to______________ gm |

Limit: ___________ gm

to______________ gm

|

Limit: ___________ gm

to_______________gm |

||||

| Note: Limits shall be calculated considering the actual mass value of the weight. | ||||||||

- Remarks: The Calibration of the instrument found satisfactory / Not satisfactory.

Eccentricity :

| Weight used | Actual mass value(g) | Observed Weight (in g)

Limit : All weights should be ±0.05 % of actual mass value. |

||||

| Limit as per actual mass value : Min __________gm to Max_________gm. | ||||||

| 100 gm |

|

Wt of Position -1

|

Position -2 | Position -3 | Wt of Position – 4 | Position – 5 |

|

|

||||||

- Remarks: The Calibration of the instrument found satisfactory / Not satisfactory.

-

Repeatability :

| Date

|

Weight used

|

Weight Box No. & Valid up to

|

Observed Weight

|

Mean

|

Standard deviation

|

Value of 0.41d

|

Repeatability

Limit: NMT 0.0010

|

Done by

|

Checked by

|

Remark

|

||||

| 100 mg

|

||||||||||||||

| 100 gm

|

||||||||||||||

-

Repeatability :

Calculation:

- For 100 mg

Standard deviation/ 0.41d value x 2

Repeatability = ——————————————— = ——————————- = __________

Nominal value of the weight used for the desired smallest net weight.

- For 100 gm

Standard deviation/ 0.41d value x 2

Repeatability = ——————————————— = ——————————- = __________

The nominal value of the weight used for the desired smallest net weight.

Remarks: The Calibration of the instrument found satisfactory / Not satisfactory.

Annexure-3: Calibration Status Label.

|

CALIBRATION STATUS |

| Instrument :________________________________________

Code : _____________Model:_______________________ Frequency :________________________________________ Done on : ________________Due on :__________________ Status : Instrument found satisfactory for analytical use Done By :____________ Checked By :___________________ Date :_______________ Date : _____________________ |