Standard Operating Procedure (SOP) for Analyst/Chemist Qualification, Data Reviewer Qualification through performing parallel Analysis, and other evaluation parameters.

Procedure of Analyst / Reviewer Qualification

1.0 PURPOSE:

-

- The purpose of this SOP is to describe the procedure for analyst/reviewer qualification.

2.0 SCOPE:

-

- The SOP is applicable for analyst/reviewer qualification in the Quality Control department at the pharmaceuticals drug manufacturing plant.

3.0 REFERENCES:

-

- In House.

4.0 RESPONSIBILITY:

-

QC Personnel shall be responsible for:

-

- To perform the activity as per the SOP and respective specifications.

-

- To maintain the records as per SOP.

-

Quality Control Head or Designee shall be responsible for:

-

- To check the SOP.

-

- To give training to all concerned persons before the implementation of SOP.

-

Quality Assurance shall be responsible for :

-

- To check the SOP.

-

- To ensure the implementation of

-

Site Quality Head shall be responsible for:

-

- To review and approve the SOP.

5.0 ABBREVIATIONS USED IN SOP FOR ANALYST QUALIFICATION:

-

- AR.No. : Analytical Report Number

-

- FP: Finished Product

-

- IR: Infrared

-

- LOD: Loss on Drying

-

- MLT: Microbial Limit Test

-

- OR: Optical Rotation

-

- PM: Packing Materials

-

- RS: Related Substances

-

- RSD: Relative Standard Deviation

-

- UV: Ultraviolet

7.0 PROCEDURE FOR ANALYST AND REVIEWER QUALIFICATION:

-

Analyst Qualification :

-

- After the completion of induction training and departmental training of new entrant, QC Head shall decide the section of analyst for working as per the previous experience of the new entrant.

-

- Section in-charge shall coordinate the analyst qualification program for new entrants along with the training coordinator.

-

- Analyst qualification of new entrant shall be based on the individual job responsibility of analyst with the respective section.

-

- Section head or designee shall identify the instruments for analyst qualification beyond its make and model.

For example: If a laboratory has HPLC of different make, it is not required to give the training on each make for qualification.

-

- Instrument and test wise qualification shall be done for the analyst as per Annexure-1.

-

- The analyst shall not be allowed to perform the analysis on a specified instrument or to perform a test for which the analyst is not qualified with respect to training.

-

- A trained analyst shall be allotted for the parallel analysis with the trainee (wherever applicable).

-

- Control samples shall not be taken for analyst qualification.

-

- Section in-charge in coordination with the training coordinator shall allot following samples to the analyst for analyst qualification (but not limited to):

-

-

Samples for Analyst Qualification :

-

-

-

- Samples that are pending for approval or are under analysis (if the quantity is sufficient).

-

-

-

- Working standard or lots prepared from working standard.

-

-

-

- Expired lots of finished products or completed stability samples.

-

-

- The sample shall be provided with proper code numbering, analytical test procedure, and analytical worksheet to note down the raw data and calculation of results.

-

- For analysts in Raw material, Finished product, Stability, Microbiology, and packing material and WS sections, etc. the qualification shall be done as per specifications mentioned in Annexure – 1 and 2.

-

- Code number of sample for analyst qualification shall be assigned as follows: XX/YY/ZZZ where,

-

-

- XX = Initial two letter of product/material name.

-

-

-

- YY = Current year, e.g. for the year 2020, YY=20

-

-

-

- ZZZ = Alpha numeric number in series (e.g. 001, 002, 003 . . . . . . . .)

-

For Example, Raw material of Calcium Carbonate is allotted to any analyst for his/her analyst qualification, then the code numbering for the sample shall be assigned as CC/20/001.

-

Analyst Qualification – Analytical Activity:

-

- The analyst shall analyze the given sample in as per the “specification for qualification” given in Annexure -2 ( but not limited to).

-

- Balance and pipetting qualification shall be done as per Annexure-3.

-

- The analyst shall pipette out the desired volume of sample/ water/ reagents/solvents etc. and shall transfer it into a suitable clean and dry receiver (e.g beaker, volumetric flask, etc) to record the weight of the respective liquid sample in Annexure-3.

-

- The pipetting and weighing shall be done in triplicate.

-

- The RSD of the three weights shall not be more than 0.5%.

-

- The analyst shall record all the raw data in the template provided and shall calculate the results in Annexure -2.

-

- The analyst shall enter the calculated result in the calculation sheet/module/software, attach the respective chromatograms, UV readings, IR graphs, etc with the report and shall submit the report to section in-charge / reviewer for checking.

Related: SOP for Analytical Data Review

-

-

Evaluation of Analyst Qualification Raw Data-

-

-

- Section in-charge/ reviewer shall review the report with respective specifications and analytical test procedures.

-

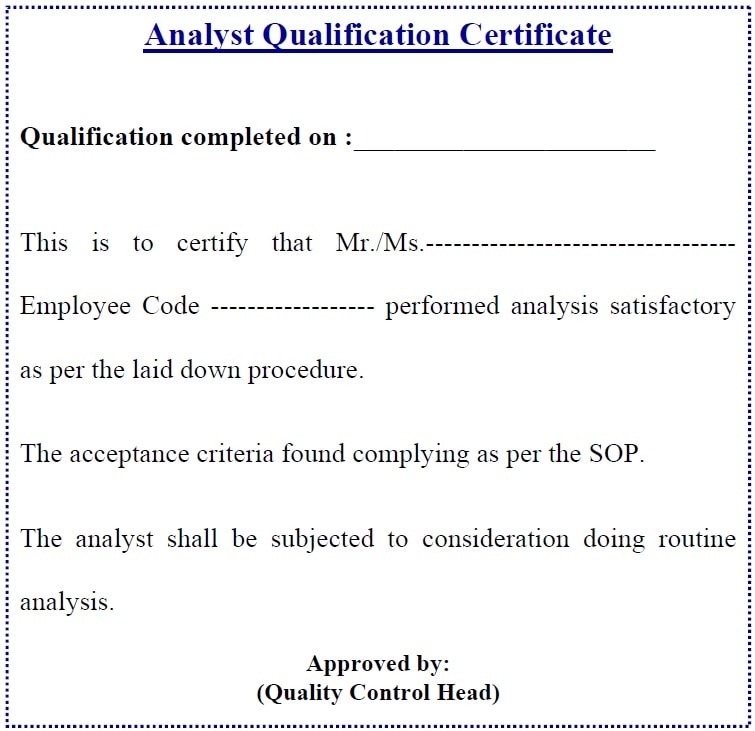

- Section in-charge/ reviewer shall compare the test result of the trainee analyst with that of the trained analyst and if the results are comparable and within the acceptance limit, then the analyst shall tabulate both results in Annexure-4 (Evaluation of analyst qualification data) and prepare the analyst qualification certificate as per Annexure – 5

-

- After reviewing the report, section in-charge shall handover the report to QC head for final approval where the QC Head shall approve the analyst qualification certificate.

-

- After the approval of the analyst qualification certificate, the analyst can perform the testing in the respective section allotted to him/her by the QC head.

-

- If the results are not comparable and not within the acceptance limit, then the analyst needs retraining and needs to re-qualify.

-

- For fresher candidates, analyst qualification shall be conducted only after giving proper training to the candidate.

-

Reviewer Qualification :

-

- The reviewer shall be qualified by reviewing a dummy template containing several errors.

-

- The reviewer needs to identify the errors in the template provided to evaluate their reviewing capabilities.

-

- The outcome of the reviewer’s findings shall be verified against the known errors listed in a separate answer sheet.

-

- The evaluation of the reviewer qualification shall be done in Annexure-6 (but not limited to) by the training coordinator/designee and

-

- Handover the data to QC head for final approval where the QC Head shall approve the reviewer qualification certificate.

8.0 ANNEXURES – SOP FOR ANALYST QUALIFICATION:

-

-

Annexure-1: Code numbering register.

-

|

Sr. No |

Sample name | Code No. | Tests | Issued to | Issued by

(Sign & Date) |

Remarks |

-

-

Annexure-2: Analytical worksheet.

-

| Sample Name : | Analyst Name : | |

| Code No.: | Employee code: | Test : |

-

-

Annexure-3: Balance and pipetting qualification sheet.

-

Analyst Name : _________________________ Designation:_______________

Employee Code:___________

| Date | Bulb pipette | Weight result | RSD % | Analyst’s sign and date | Remarks | ||

| Ist Set | IInd Set | IIIrd Set | |||||

| 1ml | |||||||

| 2 ml | |||||||

| 5 ml | |||||||

| 10 ml | |||||||

| Acceptance Criteria: RSD of three weights shall not be more than 0.5% | |||||||

Remarks: The trainee is qualified / not qualified for performing pipetting and weighing.

Evaluated by :__________________;

-

-

Annexure-4: Evaluation of analyst qualification data.

-

Analyst Name : _________________________ Designation:_______________

Employee Code:___________

Prepare the table with the following table content…

-

- Sr. No.

-

- Sample Name

-

- Batch No./A.R.No

-

- Test

-

- Instrument

-

- Result of the trained analyst

-

- Result of trainee analyst

-

- Mean /RSD of trainee’s results

-

- Difference between the two analysis

-

- * Remarks

Evaluated by :

Remarks : * Note: 1) Put “Not applicable”, “Qualified”, “Not qualified” in the remarks column (whichever is applicable).

2) The trained analyst shall be attached only where applicable.

-

-

Annexure-5: Analyst Qualification Certificate.

-

-

-

Annexure-6: Evaluation sheet for Reviewer Qualification.

-

Name of the Trainee: Designation :__________________________

Employee Code :___________________________

| Template Issued By/Date : |

| Topic: Review of dummy template.

Product/ Material name : |

| Errors identified by reviewer: |

| Errors not identified by the reviewer: |

| Total no. of errors in the template : |

| No. of errors identified by the Reviewer : |

| % Evaluation : ( Evaluation criteria : Not less than 80%) |

| Evaluation: The trainee has understood/not understood this phase of the training and Qualifies/Does not qualify for the analytical raw data review. |

Evaluated By: Date :

-

-

Annexure-7: Reviewer Qualification Certificate.

-

(Refer to Annexure 5 and replace the word “Analyst” with “Reviewer”)

-

-

Annexure-8: Instrument and test wise Qualification.

-

|

Instrument name |

Test |

| HPLC/UPLC/UV/Polarimeter/GC | Assay/ RS/ Dissolution/ Content uniformity |

| Titrimetry | Assay |

| Karl fisher/coulometer | Water Content |

| LOD by oven/TGA/halogen moisture balance | LOD |

| Dissolution apparatus | Dissolution |

| DT | Disintegration test |

| Friability | Friability determination |

| Balance | Weight |

| Muffle furnace | Residue on ignition/sulfated ash/other tests which is specific on muffle furnace |

| Particle size analyzer/sieve shaker | Particle size determination |

| pH Meter | pH determination |

| Melting point | Melting point determination |

| Conductivity meter | Conductivity measurement |

| Infrared | IR Test |

| Ultraviolet (UV) | Color, clarity, specific absorbance determination |

| Polarimeter | SOR or OR determination |

| Bursting strength apparatus | Bursting strength test (Packing) |

| Any other instrument ( If required ) | Shall be ensured by Training coordinator/ Section head/QC Head |

-

-

Annexure-9: Specification for Qualification.

-

|

Test |

Trained analyst |

Trainee |

| Assay | In Single | 1. Test Three replicate preparations 2. RSD of three results should not be more than 1.0 % 3. Result difference from the trained analyst and trainee ± 2.0% |

| Water/LOD | In Single | 1. Test Three replicate preparations 2. RSD of three results should not be more than 1.0 % 3. Result difference from the trained analyst and trainee ±1.0 % |

| IR

|

Single preparation

(Purity index shall not be less than 0.95) |

1. Test Three replicate preparations

2. Purity index of all the three results shall not be less than 0.95 |

| Dissolution | Single preparation | 1. Test two set preparation (six bowls each set) 2. RSD of three results should not be more than1.0 % 3. Result difference from the trained analyst and trainee ± 2.0 %. |

| DT | NA | Test to be carried out in the presence of section head/supervisor, to ensure the specification. |

| Friability | NA | Test to be carried out in the presence of section head/supervisor, to ensure the specification. |

| Polarimeter | Single preparation | 1. Test Three replicate preparation 2. RSD of three results should not be more than 1.0 % 3. Result difference from the trained analyst and trainee ± 2.0 % |

| UV | Single preparation | 1. Test Three replicate preparation 2. RSD of three results should not be more than 1.0 %. 3. Result difference from the trained analyst and trainee ± 2.0 % |

| Balance | NA | By pipette* taking different volumes to ensure the weighing practices and pipetting. |

* Note: The balance and pipetting qualification shall be done as per Attachment -3

Qualification for Micro test :

| Test | Trained analyst |

Trainee |

| Media preparation | NA | Shall be ensured by Training coordinator/ Section head/QC Head |

| Autoclave | NA | Shall be ensured by Training coordinator/ Section head/QC Head |

| Bioburden/MLT | NA | Single,

Shall be ensured by Training coordinator/ Section head/QC Head |

| Bioassay | Single | To be trained by the trained analyst during the activity |

| Handling and identification of culture | NA | Shall be ensured by Training coordinator/ section head/QC Head |

| Particle counter | Single | To be trained by the trained analyst during the activity |

| Antimicrobial Effectiveness test | Single | Single, and shall be ensured by Training coordinator/ Section head/QC Head |