Standard Operating Procedure (SOP) for disintegration apparatus (DT Apparatus) for operation and calibration as per IP containing various calibration parameters.

Operation and Calibration of Disintegration Apparatus (DT)

1.0 PURPOSE:

-

- The purpose of this SOP is to describe the procedure for operation, calibration, and cleaning of the disintegration apparatus.

2.0 SCOPE:

-

- This SOP is applicable to all disintegration apparatus of make: Electrolab and model: ED-4AL.

3.0 REFERENCES:

-

- Instrument manual

-

- Instrument/equipment usage log

-

- URS and Analytical Instrument/ Equipment Qualification

-

- Preparation of Internal and External (Third Party) Calibration Schedule and Calibration Practices

-

- Maintenance of Laboratory Instruments

4.0 RESPONSIBILITY:

-

-

The analyst shall be responsible for:

- Follow the procedure as per the

-

-

- Carry out documentation as per the SOP.

-

Quality Control Head or Designee shall be responsible for:

- Check the SOP.

-

- Provide training to all the concerned persons before the implementation of the

-

- Ensure the implementation of the SOP.

-

- Ensure that the instrument is calibrated and operated as per the SOP.

-

- Check the records.

-

- Execute the Out of calibration in case of calibration failure and in case of breakdown intimate to the Quality Head.

-

Quality Assurance shall be responsible for:

- Check the SOP.

-

- Ensure the implementation of system as per the SOP.

-

Site Quality Head shall be responsible for :

- Approve the SOP.

5.0 DEFINITION:

-

- Complete disintegration: That state in which any residue of the unit, except fragments of insoluble coating or capsule shell, remaining on the screen of the test apparatus or adhering to the lower surface of the disk, if used, is a soft mass having no palpably firm core.

Also read: SOP for Audit Trail Review and Privilege Policy

7.0 PROCEDURE FOR HANDLING OF DISINTEGRATION APPARATUS:

-

-

Start-Up:

- Place the instrument on a leveled sturdy surface.

-

-

- Fill the bath with water up to the level marked and check the water level in the instrument and replace the water if required.

-

- Place the bath top plate on the bath such that the cut on the plate matches with the notch on the bath.

-

- Connect the main supply, heater connector, and external probe into their respective sockets provided at the rear right-hand side of the instrument.

-

- Fill the beakers of 1-liter capacity with approximately 800 ml, The volume of liquid is such that the wire mesh at its highest point is at least 25 mm below the surface of the liquid and at its lower point is at least 25 mm above the bottom of the beaker.

-

- At no time shall the top of the basket – rack assembly becomes submerged.

-

- Connect the basket to the basket hook

-

- Switch “ON” the instrument

Also visit : HPLC Calibration- A Complete Guide

-

-

Set the temperature to 37.0°C as follows :

- Press SET key 3and then TEMP key

-

-

- The display will show the last set temperature and the first digit (Decimal digit) will blink.

-

- Using the UP 5or down6 keys, select the first digit.

-

- To move to the other digits positions use the set key 3 and using up /down keys select the value as 37.0.

-

- Press enter to accept the selection.

-

Set the timer of the respective timers as follows:

- To select the Hour: Minute mode (HH: MIN) press UP key 5 and press the timer 1 or Timer 2 for which the setting is being set.

-

- The display will change to HH: MIN mode. A – sign on the display will indicate this.

-

- To set the timer to Minute: Second (Min: Sec.) mode Press down 6 key and press the timer for which the mode is to be applied.

-

- To set the time press set key, the timer in which time setting is done and select the value using Up/down keys (for selecting the values) and the set key (for selecting the decimals).

-

- After the selection of the values. Press enters to accept the timer setting for the particular timer.

-

- To start the instrument-using manual timer, press the toggle Key “ Timer/Manual” key.

-

- The manual timer is indicated by “__ __ __ __” display on the timer.

-

- In the manual timer mode the instrument will not stop automatically, but to be stopped manually.

-

- Start/Stop key is a toggle key for the Timer. If this key is followed by the particular Timer key then it is used to start and stop both the timers independently.

-

- If a display on temperature display shows a ‘P.O’, this indicates that the probe is open. Connect the probe. Also, a display of ‘P S’ shows that the probe is a short condition.

-

Operational Procedure of Disintegration Test Apparatus :

- By pressing the toggle key of ‘PROBE SELECT’ check the temperature of the bath and ensure the set temperature is reached.

-

- Put the probe in the beaker and press the Probe select toggle key to select ‘EXT’

-

- If the temperature of the disintegration medium reached to set temperature then add to the samples into the basket assembly with disc or without disc, as per requirement

-

- To start the test, press START/STOP key and the timer key of the particular basket assembly on which the sample is placed.

-

- Press again the timer key to halt the instrument in between the set time.

-

- The timer will show a steady glow when it is on and a blinking glow when it is halted and no glow when the test is over or when not in use.

-

- At the end of the set time, the instrument will stop automatically.

-

- The time will show on the timer display.

-

- Record the time at which all the six dosage forms (tablets or capsules) get disintegrated.

-

Calibration frequency :

- Temperature, cycles per minute, timer and distance of up/down cycle check (Calibration frequency: Monthly ± 3 days.)

-

- Checking of Disks parameters. (Calibration frequency: Quarterly ± 7)

-

- Checking Basket Rack Assembly parameters (At installation and replacement)

-

Recalibration of Disintegration Test Apparatus:

- In case of maintenance (change /repair) of heater and temperature sensor, Temperature calibration shall be performed.

-

- Decide the calibration requirement for other maintenance cases by case basis.

-

- Calibration procedure: Perform the calibration and record readings in the template as per Annexure -1.

-

Temperature:

- Set the temperature 37°C.

-

- After achieving the temperature between 35° – 39°C, insert the calibrated thermometer in the immersion fluid in the beaker which is water.

-

- The temperature difference between the temperature display of the apparatus(sensor) and the calibrated thermometer shall not be more than ± 0.5°C.

-

- Note the temperature display and thermometer reading in the template

-

- Up/down cycles Set the time for 1 minute.

-

- Record the cycles for one minute by using a previously calibrated stopwatch in the template.

-

- Up/down cycle shall be 29-32 per minute.

-

Timer – Disintegration Test Apparatus:

- Set the timer for 15 minutes.

-

- Start the timer and calibrated stopwatch at a time, stop the stopwatch as soon as the timer reaches 15 minutes’ time. Note the time of timer display as well as of stopwatch and enter the data in the

-

- The timer shall be within ± 2% of the calibrated stopwatch.

-

Distance measuring between up/down cycles :

- Put the scale against the basket rack assembly in a vertical position.

-

- Start the apparatus and note the value in mm from the scale of UP and DOWN positions.

-

- Subtract the DOWN position value from the UP position value and record in the template.

-

- The distance of the up/down cycle shall be between 53-57 mm.

-

- Perform scheduled calibration for Disk as per Annexure -2 using vernier calipers and observe visually for non-blockage of holes.

-

- Perform the calibration at the time of installation and replacement for basket rack assembly as per Annexure -3 using vernier calipers or verify the compliance as per Vendors COA.

-

Analytical practices: Disintegration Test Apparatus:

- The Disintegration Test Apparatus shall consist of basket rack assembly with a 1000m1 low form beaker, for the immersion fluid, a thermostatic arrangement for heating the fluid between 35° and 39°C.

-

- The volume of immersion fluid in the vessel is such that at the highest point of upward stroke the wire mesh remains at least 15mm below the surface of the fluid and descends to not less than 25mm from the bottom of At no time should the top of the basket rack assembly become submerged.

-

- Place 1 dosage unit in each of the six tubes of the basket and, if prescribed add a disk. Operate the apparatus using about 800m1 of the specified medium as the immersion fluid, maintained at 37 ± 2°.

-

- Record the time at which the last of six units have disintegrated completely.

-

- If at the end of the time limit specified 1 or 2 tablets fail to disintegrate completely, follow the respective pharmacopoeial criteria for a further stage, analysis.

-

Cleaning of Disintegration Test Apparatus :

- Tube and bath: Fill half bath with 2.0 % non-ionic detergent solution ( e.g Tipol ) and circulate for about 10 minutes and then with purified water. Perform the activity twice a week.

-

- Fill the cleaning log as per Annexure.4.

-

- After completion of the test, clean the instrument as per the respective cleaning procedure.

-

Precautions:

- Fill the water bath with purified water only.

-

- Before starting the test, always check for the programmed parameters.

-

- Check for the water level in the bath.

-

- Inlet & outlet tube shall be free from air entrapped.

-

- Check for the calibration status of the instrument before use.

8.0 ANNEXURES:

-

-

Format for Calibration Template For Disintegration Apparatus (Annexure -1).

-

| Instrument Name | Disintegration Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Monthly ± 3 days | |

| Calibration Date | Next Calibration due on | ||

| Sr .No. | Type of calibration | Set value | Observed value | Limit |

|

1 |

Temperature | 37°C | Bath temperature:

( It shall be between 35°C to 39°C)

Temperature difference between Digital display of apparatus and thermometer ± 0.5°C |

|

|

2 |

Cycle | 1 min* | 29 to 32 | |

|

3 |

Timer | 15 minutes | 14.7 to 15.3 minutes | |

|

4 |

The distance of the UP/DOWN cycle | NA | 53 to 57 mm |

* Set the timer for 1 minute and record the cycles for one minute in the observed value column.

Remarks : _______________________________________________________________

| Calibration status : Satisfactory / Not Satisfactory | |

| Calibrated By : | Checked By : |

| Date : | Date : |

-

-

Calibration template for disk (Annexure -2).

-

| Instrument Name | Disintegration Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | Quarterly ± 7 days | |

| Calibration Date | Next Calibration due on | ||

| Disk No. | Thickness

9.35- 9.6 mm |

Diameter

20.55- 20.8 mm |

* Hole Diameter of the disk

1.9 – 2.1 mm |

Visual observation of hole (No. of blockage ) | ||||

| 1 | 2 | 3 | 4 | 5 | ||||

* Perform if any deformation observed in a disk shape.

Remarks :_______________________________________________________________

| Calibration status : Satisfactory / Not Satisfactory | |

| Calibrated By : | Checked By : |

| Date : | Date : |

-

-

Format for Calibration template for basket rack assembly (Annexure -3).

-

| Instrument Name | Disintegration Apparatus | ||

| Instrument Code | Make/Model | ||

| Location | Calibration frequency | ||

| Calibration Date | Next Calibration due on | ||

|

Sr, No. |

Parameters |

Limits |

Observed value |

|

1 |

Plastic plate diameter |

88 – 92 mm |

|

|

2 |

Plastic plate thickness |

5.0 – 8.5 mm |

|

|

3 |

Plastic plate hole diameter |

22 – 26 mm |

|

|

4 |

Mesh size |

1.8 – 2.5 mm |

|

|

5 |

Wire diameter |

0.57 – 0.66 mm |

Remarks :_______________________________________________________________

| Calibration status : Satisfactory / Not Satisfactory | |

| Calibrated By : | Checked By : |

| Date : | Date : |

-

-

Cleaning record for DT apparatus – Tube and Bath (Annexure -4).

-

| Instrument ID No. : | Location : |

|

Date |

Cleaning | Done By |

Checked by |

|

|

From |

To |

|||

-

-

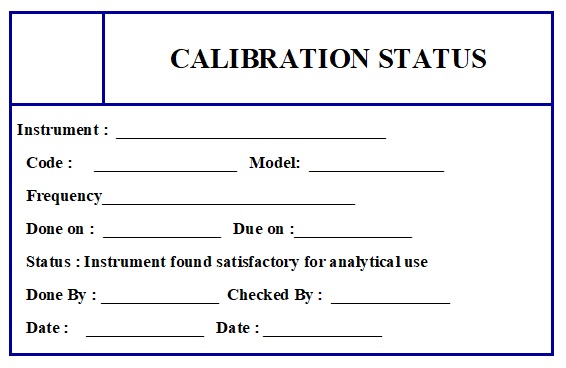

Format for Calibration status label (Annexure -5).

-

Next to read :

- HPLC Calibration- A Complete Guide.

-

- Calibration of UV Spectrophotometer

-

- Procedure for Laboratory Glassware Cleaning.

-

- Quality Control Samples.

-

- Good Laboratory Practices for Workbench

-

- Functions and Reporting system of Quality Control Department in Pharmaceuticals.

-

- Raman Analyzer – Handling Procedure (SOP)

Pingback: Analyst Qualification SOP in Quality Control - Pharma Beginners

Pingback: In process Quality Control (IPQC) Check Procedure - Guidelines - SOPs

Pingback: SOP for Instrument Calibration (Internal & Third Party) - Pharma Beginners

Pingback: SOP for Audit Trail Review and Privilege Policy - Pharma Beginners

Pingback: SOP for Operation and Calibration of UV Cabinet - Pharma Beginners