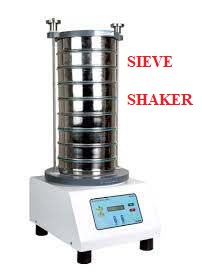

Standard Operating Procedure (SOP) for Operation and Cleaning of Electromagnetic Sieve Shaker which is used to determine the particle size of pharmaceutical starting material (API and Excipients).

SOP for Electromagnetic Sieve Shaker

1.0 Purpose:

-

- The purpose of this SOP ( Standard Operating Procedure) is to describe the operation of Electromagnetic sieve shaker.

2.0 Scope:

-

- This SOP is applicable to the following Electromagnetic sieve shakers at the quality control Department.

| Make | Model | ||

| Electrolab | EMS – 8 | ||

| Electrolab | EMS – 8 |

3.0 References – SOP for Sieve Shaker :

-

-

References :

-

-

- SOP for Instrument/Equipment usage log book.

-

- Operation Manual Provided by Manufacturer for Sieve Shaker

-

- SOP for Preparation of internal and external (Third Party) Calibration schedule and calibration practices.

4.0 Responsibilities – SOP for Sieve Shaker

-

-

Analyst :

-

-

- To follow the procedure for operation of the sieve shaker as per SOP

-

- To maintain the logbook, history card of Sieve Shaker

-

-

Quality Control Head or Designee :

-

-

- To review and approve the

-

- Implementation of the system as per SOP.

-

-

Quality Assurance:

-

-

- To ensure the implementation of the system as per SOP.

- Abbreviation:

5.0 Procedure for Operation of Sieve Shaker:

-

-

General Procedures

-

-

- In case of noticing any malfunctioning of the instrument, follow SOP on Maintenance of Laboratory Instrument.

-

- Follow the SOP on Instrument/Equipment usage logbook, for the entry of usage of the instrument.

-

- Preparation of internal and external (Third Party) Calibration schedule and calibration practices.

-

-

The operational procedure of Sieve Shaker

-

-

- Place the sieve shaker in a flat surface preferably on a rubber sheet.

-

- Use certified sieves.

-

- Select the sieves required as per monograph/procedure.

-

- Check the integrity of the sieves.

-

- Ensure the sieve numbers are matching with the ASTM number given on the sieves.

-

- Place the sieves in the descending order of sieve No. on the collecting pan.

-

- Adjust the required time as per individual monograph using the time UP/DOWN key on the front panel.

-

- Adjust the power using the power UP/DOWN key on the front panel.

-

- To select Continuous or Intermittent sieve shaking push respective keys on the front panel.

-

- Weigh the sample and evenly spread the same on the top sieve and close the sieve.

-

- Place the sieve sets on the base of the holder firmly and lift the assembly to touch the top of the holder.

-

- Tight the assembly and switch on the mains.

-

- Then press the START key to start the operation.

-

- After completion of the process carefully remove the sieves set.

-

- Collect the samples retained on each sieve and on the collection pan and weigh the quantity of sample retained on each sieve.

-

- Calculate the percentage of the sample retained on each sieve and report.

-

- Check the integrity of the sieves again, If not OK label it as rejected and discard the same as scrap.

-

- Clean the sieves with water and dry.

-

- Ensure the holes of the sieves are not blocked.

-

- Store in a separate place.

-

- Use the sieves having the same diameter so that they will fit best in the assembly.

-

- Timer calibration is done by External agency every year.