Standard Operating Procedure (SOP) for sampling from different points and microbiological analysis/testing of Purified water samples in pharmaceutical plants.

Sampling and Testing of Purified Water in Microbiology

1.0 PURPOSE:

-

- To lay down the procedure for Sampling and Testing of Purified Water.

2.0 SCOPE:

-

- This Standard Operating Procedure is applicable to the Microbiology Department.

3.0 REFERENCE:

-

- Aseptic Technique for Microbiological Testing.

-

- Quality Monitoring of Water for Pharmaceutical Use.

-

- SOP for Analysis of Water Samples.

-

- IP/BP/USP

4.0 RESPONSIBILITY:

-

- Officer or Executive of the Microbiology department shall be responsible for the preparation of new or revision of existing SOP.

-

- Head of the Department / Designee of respective areas & QA shall be responsible for reviewing the SOPs.

-

- Head QA shall be responsible for the approval of SOP.

5.0 ABBREVIATIONS:

-

- CCR: Change Control Record

-

- CFU: Colony Forming Unit

-

- COA: Certificate of Analysis

-

- °C: Degree Celsius

-

- HCL: Hydrochloric Acid

-

- IPA: Isopropyl Alcohol

-

- ML: Millilitre

-

- ppb: Part per Billion

-

- TOC: Total Organic Carbon

6.0 DEFINITION:

-

-

Alert limit:

-

-

- Microbial levels, specified in the standard operating procedure or specifications, when exceeded should result in an investigation to ensure that the process is still within control.

-

- Alert levels are specific for a given facility and are established on the basis of a baseline developed under an activity monitoring program.

-

- These Alert levels can be modified depending on the trend analysis done in the monitoring program. Alert levels are always lower than Action levels.

7.0 PROCEDURE FOR SAMPLING AND TESTING OF PURIFIED WATER:

-

Preparation of Containers for the sampling of purified water:

-

- For Chemical Analysis:

-

- Clean 1000 ml Clear glass bottles with a cap. Rinse with purified water.

-

- For TOC analysis:

-

- Wash 125 ml Amber glass or suitable bottles with a stopper with 2.0 M HCL or 2.0% nitric acid and rinse with purified water and dry the bottles at 105 ºC for at least one hour.

-

- For Microbiological Analysis:

-

- Clean 250 ml Clear glass bottles with cap for membrane filtration method or pour plate method and rinse with purified water.

-

- Close the bottle with a cap and wrap the neck with aluminum foil and Sterilize the bottle at 121 ºC (15 lbs.) for validated time.

-

Sampling Schedule of Purified Water:

-

- Refer Annexure-2 for preparing the Sampling Schedule. make the schedule in such manner that generation point (For Chemical & Microbiology Analysis) & return loop (For Microbiology Analysis only) covered on a daily basis and other useful points (For Microbiology Analysis only) to be covered in rotation within a month.

-

- Prepare the sampling schedule (Tentative) by the first working day of every New Year.

-

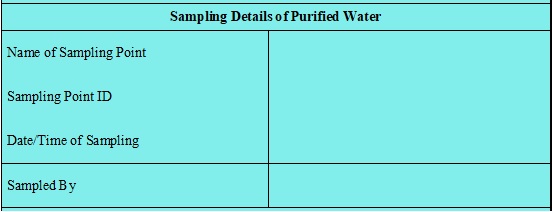

- Write the sampling details or affix the label on the bottle as per Annexure-3.

-

- Carry the sampling containers to the sampling point as per the sampling schedule.

-

- Sanitize the hands with 70 % v/v IPA. Wear gloves and nose mask before sampling.

-

- Open the valve of the sampling point and allow the water to drain for about 20-30 seconds.

-

Collection of purified water for Chemical and TOC analysis:

-

- Rinse the container at least one to two times with purified water from the sampling point.

-

- Fill the containers with 1000 ml and 125 ml or up to the neck of purified water for chemical and TOC analysis respectively, and close the lid immediately.

-

- Analyze the TOC sample as quickly as possible on arrival at the laboratory.

-

- If the immediate analysis is not possible to acidify the sample with a 2-3 drop of 2.0 M HCL and store the sample under refrigeration at 2 to 8ºC.

-

- These stored samples should be analyzed within 6 hours.

-

Collection of purified water for Microbiological analysis:

-

- Hold the sterile container near the sampling point.

-

- Unwrap the aluminum foil and open the bottle taking care not to touch the inner surface and neck of the bottle.

-

- Collect the purified water sample (refer table 1) without rinsing and close it with stopper immediately.

-

- Do not fill the bottle up to the neck.

-

- Wrap the neck with aluminum foil to avoid any contamination during transportation.

-

- Close the valve and bring the samples to the laboratory and make an entry in the purified water inward register.

-

- Perform the analysis as per the current version of purified water specification.

-

- Analyze the sample as quickly as possible on arrival at the laboratory.

-

- If the immediate analysis is not possible, store the sample under refrigeration at 2 to 8ºC.

-

- These stored samples should be analyzed within 6 hours.

Table 1

| Test parameters | Sample quantity | Sample bottle |

| Chemical analysis | 1000 mL | Non-sterile |

| TOC analysis | 125 mL | Non-sterile |

| Microbiological analysis | 250 mL | Sterile |

-

Issuance of purified water analysis template:

-

- Before analysis, Register/log the sample, and generate/issue the worksheet, or the template.

-

- A designated person shall issue the template/worksheet.

-

- Analyze the sample of purified water for Total Viable Count using filtration technique as per the current specification of Purified Water.

-

Pathogen testing of purified water:

-

- Analyze the sample of purified water for pathogens using filtration technique/Direct as per the current specification of Purified water.

-

- Carry out the chemical analysis of samples as per the current version of purified water specification.

-

Sampling Precautions – Purified Water:

-

- Utility system sampling requires additional care because samples are collected in controlled and uncontrolled areas of the facility.

-

- Sampling personnel shall wear clean smocks or gowns and sterile gloves prior to collecting any sample (As per area requirements).

-

- Sampling apparatus and containers shall be clean, sterile, and/or endotoxin-free as per test requirements.

-

- Wipe any visible dust from the exterior of the sample port or valve using a lint-free wipe/cloth moistened with an approved sanitizer – do not spray or wipe the interior of the port or valve.

-

- Ensure that the required contact time for the sanitizer has been achieved.

-

- If a hose is already connected to the port or valve, collect the sample directly from that hose.

-

- If the hose is not connected but is provided, attach the hose using procedures applicable for that system.

-

- Replace the used hose onto the provided clamp after sampling so that it fully drains.

-

- If a hose is not present, a sterilized adapter and hose may be used to sample directly from the valve/port.

-

- Flush the sample port/valve for the qualified time or volume and immediately open the labeled sample container and collect the sample.

-

- Close the container immediately and record the sampling time.

-

Frequency of Sampling of Purified Water:

| Sampling Locations | Type of Analysis | Frequency |

| Generation Point | Chemical TOC /Oxidisable Substance Total Microbial Counts Presence of Pathogens |

Daily |

| Return Loop | Total microbial counts Presence of Pathogens |

Daily |

| User Points | Total microbial counts

Presence of Pathogens |

Monthly |

- Limit: Total microbial count should not be more than 100 CFU/ml and pathogens should be absent. Total organic carbon should not more than 500 ppb.

-

Alert and action limit:

| Name of Test | Alert limit | Action limit | Specification Limit |

| pH | 6.5 | 6.8 | 5-7 |

| Conductivity (µ/S) | 3.5 | 4.4 | 5.1 |

| ROE (%) | 0.0008 | 0.0009 | 0.001 |

| TOC (ppb) | 400 | 450 | 500 |

| TMC (cfu/ml) | 65 | 83 | 100 |

-

Recording of Results – Purified Water:

- After completion of the test, record the results in the datasheet and also enter the results in the respective software/module.

-

- After completion of the analytical report, checked and approved by a designated person and after that generate the COA (if required).

Related: Checklist for review of microbiology data

-

- If any chemical parameter exceeds the limit, immediately inform the same QA, Production, and Engineering Department.

-

- If the Total bacterial count exceeds the Alert limit/Action limit, immediately inform the same to QA and Engineering personnel and investigation shall be done as per the SOP for “Handling of microbial Excursion in Water and Environment”.

-

-

A two-phase approach is suggested where:

-

-

- Phase 1 focuses on the method and the analyst; the purpose of phase 1 is to verify that the data are valid. Analyst error should be rare. Immediate resampling of the specific location where the OOT/OOS occurred must be performed, to rapidly assess the condition of the system.

-

- Phase 2 follows the determination of data validity and investigates the water system and all potentially affected lots of products.

-

- Phase 2 requires a root cause analysis and corrective action.

Related: SOP for Corrective and Preventive Action (CAPA)

-

Trending of Purified Water Results:

-

- Purified water quality parameter trending shall be done on the Monthly basis, trend charts shall be reviewed and a conclusion shall be made (if required).

-

- The final summary report shall be prepared at the end of the Year.

-

Identification of Microorganisms (Water Isolates):

-

- It is important to routinely identify organisms recovered from water systems when:

-

- Waterborne organisms may be detrimental to finished products or processes in which the water is used.

-

- There is a need to identify the source of contamination.

-

- Water system sanitization methods require assessment.

-

- It is important to note that you don’t have to exceed specification in order to submit a result for identification, it’s a best practice to document and select and identify representative flora from the system.

8.0 ANNEXURES – PURIFIED WATER:

-

-

Annexure-1: List of Sampling Points of Purified Water.

-

| Sr. No. | Name of Location | Sample ID No. |

| 1. | PW Storage Tank Service Floor | PW 01 |

| 2. | After UV Treatment | PW 02 |

| 3. | Blender Granulation-III | PW 03 |

| 4. | Dry Mill Granulation-III | PW 04 |

| 5. | FBD Granulation-III | PW 05 |

| 6. | Paste Preparation Granulation-III | PW06 |

| 7. | RMG Granulation-III | PW 07 |

| 8. | Miller and Sifter Granulation-III | PW 08 |

| 9. | Blender Granulation-IV | PW 09 |

| 10. | Dry Mill Granulation-IV | PW 10 |

| 11. | RMG Granulation-IV | PW 11 |

| 12. | Miller and Sifter Granulation-IV | PW 12 |

| 13. | Paste Preparation Granulation-IV | PW 13 |

| 14. | Washing Area Second Floor | PW 14 |

| 15. | Cleaning Of Equipment Second Floor | PW 15 |

| 16. | Coating Solution Preparation Area II | PW 16 |

| 17. | Coating Solution Preparation Area I | PW 17 |

| 18. | Capsulation III | PW 18 |

| 19. | RMS Washing | PW 19 |

| 20. | Coating I | PW 20 |

| 21. | Coating II | PW21 |

| 22. | Coating III | PW 22 |

| 23. | Coating IV | PW 23 |

S. No. |

Name of Location |

Sample ID No. |

| 24. | Coating V | PW 24 |

| 25. | Coating VI | PW 25 |

| 26. | Coating Washing Area | PW 26 |

| 27. | Blender Granulation II | PW 27 |

| 28. | Dry Milling Granulation II | PW 28 |

| 29. | Washing Area Packing | PW 29 |

| 30. | FBD Granulation II | PW 30 |

| 31. | RMG Granulation II | PW 31 |

| 32. | Sifting and Milling Granulation II | PW 32 |

| 33. | Sifting and Milling I Granulation I | PW 33 |

| 34. | RMG Granulation I | PW 34 |

| 35. | FBD Granulation I | PW 35 |

| 36. | Dry Mill Granulation I | PW 36 |

| 37. | Blending Granulation I | PW 37 |

| 38. | Paste Preparation I | PW 38 |

| 39. | Paste Preparation II | PW 39 |

| 40. | Washing area compression | PW 40 |

| 41. | Compression-17 | PW 41 |

| 42. | IPQC I | PW 42 |

| 43. | Coating IX | PW 43 |

| 44. | Coating VIII | PW 44 |

| 45. | Coating Solution Preparation III | PW 45 |

| 46. | Coating VII | PW 46 |

S. No. |

Name of Location |

Sample ID No. |

| 47. | IPQC II | PW 47 |

| 48. | Quality Control | PW 48 |

| 49. | After Mix Bed UV Inlet | PW49 |

| 50. | After Mix Bed UV outlet | PW50 |

| 51. | Return Loop of PW Storage Tank | PW 51 |

| 52. | Shifting Gr.V | PW52 |

| 53. | RMG Gr.V | PW53 |

| 54. | FBD Gr.V | PW54 |

| 55. | Dry milling Gr.V | PW55 |

| 56. | Blender Gr.V | PW56 |

| 57. | Washing Gr.V | PW57 |

| 58. | Blender Gr.VI | PW58 |

| 59. | RMG Gr.VI | PW59 |

| 60. | Miller & Shifter Gr.VI | PW60 |

| 61. | Washing Gr.VI | PW61 |

| 62. | IPQC III | PW62 |

| 63. | Coating X | PW63 |

| 64. | Coating XI | PW64 |

| 65. | Coating XII | PW65 |

| 66. | Paste preparation room Gr.VI | PW66 |

| 67. | Washing room ( New RMS) | PW67 |

| 68. | Suspension preparation area IV | PW68 |

| 69. | Granulation VII | PW69 |

S. No. |

Name of Location |

Sample ID No. |

| 70. | Granulation VIII | PW70 |

| 71. | UV inlet | PWSH01 |

| 72. | UV outlet | PWSH02 |

| 73. | SH coating | PWSH03 |

| 74. | Suspension preparation room | PWSH04 |

| 75. | IPQC | PWSH05 |

| 76. | SH washing area | PWSH06 |

| 77. | SH granulation | PWSH07 |

| 78. | SH granulation | PWSH08 |

| 79. | Dispensing | PWSH09 |

| 80. | Storeroom | PWSH10 |

| 81. | Return line drain | PWSH11 |

-

-

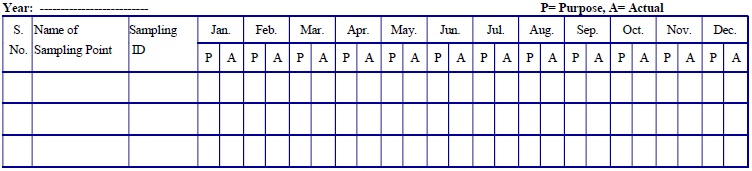

Annexure-2: Sampling Schedule of Purified Water.

-

-

-

Annexure-3: Sampling Details of Purified Water.

-

Pingback: Laboratory Glassware Cleaning of Procedure - Guidelines - SOPs

Pingback: Media Preparation for Microbiological Analysis - Guidelines - SOPs

Pingback: Purified Water Plant - Operation and Regeneration - Pharma Beginners