Standard Operating Procedure (SOP) to lay down a procedure to describe the operation and maintenance of the fire System. It also provides a guide to achieve successful fire fighting operations inside the factory premises

Procedure for Operation and Maintenance of Fire System

1.0 PURPOSE:

-

- To lay down a procedure to describe the operation and maintenance of the fire System.

-

- It also provides a guide to achieve successful fire fighting operations inside the factory premises.

2.0 SCOPE:

-

- This procedure outlined for the fire hydrant and fire extinguisher installed inside the factory premises.

-

- It shall also applicable during fire and maintenance of the fire system.

3.0 REFERENCES:

-

- In House

4.0 RESPONSIBILITY:

-

-

User Department Fire Fighters:

-

-

- The user department firefighters shall ensure the fire fighting equipment (Fire System) is readily available at the workplace and fire fighting equipment shall not block and easily accessible.

-

-

User Department In-charge / Department Head:

-

-

- User Department in-charge / Department Head ensures that fire fighting equipment is in place & not block and it also readily available to handle any fire emergency.

-

- If any deficiencies found immediately information shall be given to EHS for taking corrective action.

-

-

Engineering In-Charge / Department Head:

-

-

- Engineering in-charge / Engineering Department Head responsible to maintain preventive maintenance of fire pumps as per schedule.

-

-

EHS In-charge / Designee. :

-

-

- EHS in-charge / design. Shall be responsible to perform the following.

-

- To train all firefighters on how to operate the fire fighting equipment at fire emergency.

-

- EHS In-charge / Designee. shall be responsible for corrective actions for deficiencies are informed by any person at any time.

-

- Operation of Fire System.

-

- Other control measures shall be in place to handle the fire emergency.

5.0 ABBREVIATIONS & DEFINITION – FIRE SYSTEM:

-

- CAPA: Corrective Action Preventive Action. (SOP for CAPA)

-

- CO2: Carbon Dioxide

-

- DCP: Dry Chemical Powder

-

- EHS: Environment, Health & Safety (EHS SOPs)

-

- HOD: Head of the Department

-

- KL: Kilo Liter

-

- LPG: Liquefied Petroleum Gas

-

- PPE’S: Personal Protective Equipment’s

-

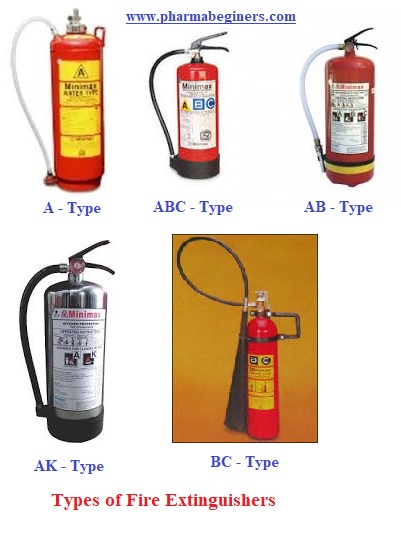

- Class A Fire Extinguisher:

-

- This type of extinguisher is created for combustible materials based on cellulose, like paper, wood or cardboard, or materials like cloth, Styrofoam, trash or plastics.

-

- Class B Fire Extinguisher:

-

- It involves flammable liquids and greases.

-

- Some examples are gasoline, kerosene, oil, paint, and solvent. and

-

- Class C Fire Extinguisher:

-

- These (Class C) extinguishers are those made for gases and electrical fire.

-

- Class D Fire Extinguisher:

-

- This kind of extinguisher is designed for a metal fire like sodium/magnesium etc.

-

- Class K Fire Extinguisher:

-

- This kind of extinguisher is designed for kitchen fire like edible fire.

-

-

Hazard:

-

-

- Any source or situation at the workplace with the potential to cause bodily injury or ill-health.

-

- Hazard can be physical, chemical, environmental, ergonomics, or biological.

-

-

Flash Point:

-

-

- Flashpoint is the minimum temperature at which it catches fire in the presence of vapor and air or oxygen.

-

-

Auto Ignition Temperature:

-

-

- It the lowest temperature at which material begins to burn without heat in presence of air.

-

-

Fire or Combustion:

-

-

- It is a rapid oxidation-reduction reaction which results in the production of heat and visible light.

-

- A substance combines with oxidant and releases energy.

-

- Part of the energy released is used to sustain the reaction. “ Fire is a good servant and a bad master ”

-

- Fire Point:

-

- The fire point is the lowest temperature at which a mixture of vapor and air continues to burn when ignited.

-

- Fuel:

-

- Fuel is a material such as wood, paper coal, oil or gas, etc. that burned to produce heat/power in the presence of heat and oxygen.

-

- It is a substance that acts as a reducing agent, giving up electrons to an oxidizer (E.g. – oxygen in the air) in chemical combustion.

-

- It may be a single compound like carbon, hydrogen, magnesium, etc., a single compound like methane CH4, a complex compound like wood or rubber, or a mixture like LPG.

-

- Fire Emergency:

-

- Fire emergency means a situation leading to circumstances or set of circumstances in which there is a danger to the life or health of the person or which could result in a big fire or explosion or pollution to the work and outside environment, affecting the workers or neighborhood in a serious manner, demanding immediate action.

-

- Explosion:

-

- It is the result of rapid exothermic reaction with a sudden, violent change of pressure involving the liberation and expansion of a large volume of gas.

-

- It affects depends on the rate at which the energy is released.

-

- The difference between fire and explosion is the rate of released energy.

-

- In the fire, it is a slow rate and in the explosion, it is at a high rate and sudden release.

-

-

Fire Chemistry and Pyramid of Fire:

-

-

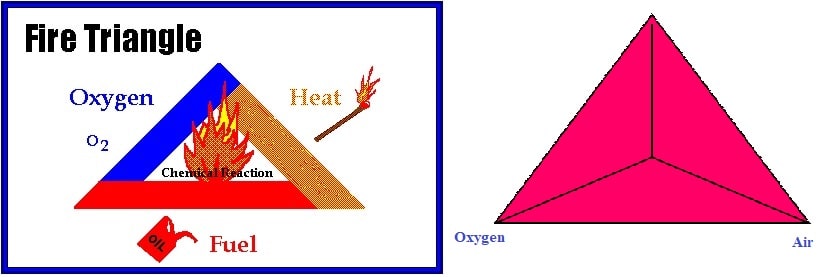

- Triangle of Fire:

-

- According to the old concept, three elements are necessary to start the fire.

-

- They are fuel, oxygen, and heat, or source of ignition.

-

- Fire is not possible if any one of these elements is not available.

-

- This is also known as the fire triangle. Shown in the below Figure.

-

-

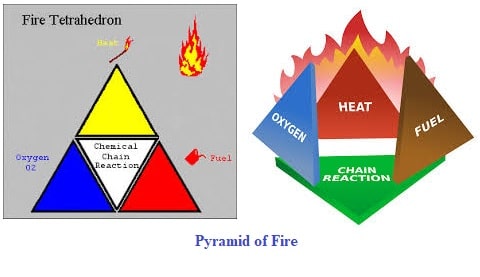

Pyramid of Fire:

-

-

- According to this concept, four elements are necessary to start the fire.

-

- Heat (combustible material and reducing agent), oxygen or oxidant or oxidizer (from the atmosphere), heat or source of ignition (necessary to start the fire initially,

-

- But maintained by the fire itself once it has started) and chain reaction through free radicals to maintain the fire. ( Shown in below Figure)

6.0 PROCEDURE – FIRE SYSTEM:

6.0 PROCEDURE – FIRE SYSTEM:

-

- The department personnel shall immediately inform the department in-charge / HOD as well as EHS about the fire incident (If any)

-

- In Fire emergency situation the user department shall perform the following:

-

- Shout Fire…., Fire…., Fire…..

-

- Call at emergency contact No. _________

-

- Seek instructions from HOD for immediate evacuation.

-

- Do not use the lift in case of fire.

-

- The area in-charge / HOD shall give information to Unit Head & Production Head (Main incident controller)

-

- Instruct the departmental firefighter to use fire extinguishers in the initial stage.

-

- Look for help from First Aiders / Fire Fighters and rescues team personals.

-

-

Operation of Fire Extinguisher.

-

-

- There are several types of fire extinguishers, Class A, Class B, Class C, Class D, Class K, etc.

-

- They have been specially designed for determining types of burning material.

-

- The operating of each class of fire extinguisher shall be done as per the steps shown on the fire extinguisher.

-

- If the fire is A-class (Wood, Paper, etc) it is suggested to use A-type extinguisher like water or available with other class of extinguisher.

-

- If the fire is B class (Liquid fire) & the suitable type extinguisher is AB, BC, or ABC.

-

- In case the fire is C class (Electric & gas) & the suitable type extinguisher is BC or ABC.

-

- If the fire is D & K type (Metal & Cooking oil) & the suitable type of fire extinguisher is ABC type.

-

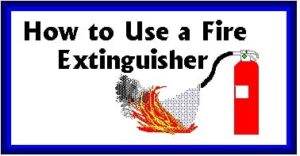

- There is a procedure for how to use fire extinguishers call PASS.

-

-

- P – Pull the pin.

- P – Pull the pin.

-

-

-

- A – Aim base on the fire.

-

-

-

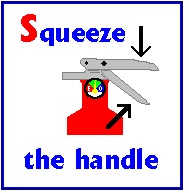

- S – Squeeze.

-

-

-

- S – Sweep on the fire

-

Pull the pin – This will allow you to squeeze the handle in order to discharge the extinguisher.

Aim at the base of the fire, aiming at the middle will do not good. The agent will pass through the flames.

Squeeze the handle – This will release the pressurized extinguishing agent.

Sweep side to side – Cover the entire area that is on fire. Continue until fire is extinguished. Keep an eye on the area for re-lighting.

-

- Fire extinguishers ID number shall be assigned as FE – XXX

-

-

- Where,

-

-

-

- FE: Fire extinguisher

-

-

-

- XXX: Representing sequential number like 001, 002.

-

-

- Fire extinguisher, types & its location shall be maintained as per annexure – 2 Revision to be done as when required by the inclusion/deletion to the item if any.

-

- Servicing of fire extinguisher shall be planned at least once in a month & shall be carried out by EHS / outside agency/service provider.

-

- At the time of servicing the following steps to be followed & same will be updated in the history card which is tagged on the extinguisher as per annexure – 3

-

- Fire extinguisher gas cartridge shall be opened and check the weight of the cartridge.

-

- The plunger shall be lubricated & it shall be easy to operate.

-

- In the case of DCP type, powder shall be dry and free of the lump.

-

- In the case of foam, check the foam solution.

-

- The pressure indicator shall be checked and it shall be on the green mark.

-

- If the indicator comes to the left side red mark that means it is empty.

-

- The discharge pipe shall be clean by suitable means to avoid the blocking of the passage.

-

- In the case of CO2 extinguishers, the discharge horn, handle, wheel, bracket, etc. shall be removed & then take weight, in case of 10 % loss of gas then send it for refilling purposes.

-

- Water type, Mechanical foam type & DCP type Fire Extinguishers shall be in hydraulically tested once in three years by a service provider or outside agency.

-

- CO2 type Extinguisher shall be hydraulically tested every 5 years by an external agency.

-

Fire Hydrant – Fire System :

-

- Hydrant Point ID number shall be assigned as HP-XX

-

- Hose Box ID number shall be assigned as HB-XX

-

- Hose Reel ID number shall be assigned as HR-XX

-

- Where,

-

-

- HP: Hydrant Point,

-

-

-

- HB: Hose Box

-

-

-

- HR: Hose Reel

-

-

-

- XX: Representing sequential numbers like 01, 02, etc.

-

-

- Revision to be done as when required by the inclusion/deletion to the item in Hydrant Point / Hose Box / Hose Reel if any.

-

- In fire Hydrant System (Fire System) inspection shall be inspected on a monthly basis and record as per annexure – 1.

-

- The report for verified by EHS In-charge / HOD EHS. Following steps shall be followed.

-

- Each fire hydrant box, pipeline , hose box, and hose reel (Fire System) shall be visually inspected to determine any defects like hydrant cracked, needs painting etc. and it shall be rectified immediately.

-

- The fire hydrant point shall be checked to ensure that threads are in good working condition, caps are in place in good condition.

-

- Fire Hydrant valves shall be opened and closed slowly to prevent damage caused by a “water hammer”.

-

- Fire hydrant line, body and bonnets shall be painted in red color.

-

-

For Hose Box service the checkpoints are –

-

-

-

- Rubber washer luges condition,

-

-

-

- Hosepipe condition,

-

-

-

- Nozzle existence & condition,

-

-

-

- Front glass condition,

-

-

-

- Hose box and hose house door,

-

-

-

- Painting & polishing.

-

-

-

For hydrant point service the checkpoints are –

-

-

-

- Wheel condition,

-

-

-

- Rubber washer condition,

-

-

-

- Lugs working,

-

-

-

- Blank cap available.

-

-

-

For hose reel service the checkpoints are –

-

-

-

- Hose reel condition,

-

-

-

- Nozzle condition,

-

-

-

- Main valve condition,

-

-

-

- Painting & polishing.

-

-

-

Details of fire hydrant system –

-

-

- Water Tank Capacity :__________

-

- Before starting the operation to check the three pumps

-

-

- Jockey pump having the capacity :_______

-

-

-

- Main electric pump having a capacity :________

-

-

-

- Diesel Generator Pump having _________. are on regular basis or as when required.

-

-

-

Checkpoints for the Jockey pump are –

-

-

-

- Valve position,

-

-

-

- Mode of operation,

-

-

-

- Vibration,

-

-

-

- Physical observation,

-

-

-

- Pump coupling & guarding line pressure.

-

-

-

Checkpoints for the main electric pump are –

-

-

-

- By pass valve,

-

-

-

- AMP reading,

-

-

-

- Vibration,

-

-

-

- Valve condition,

-

-

-

- Pump coupling & guarding,

-

-

-

- Physical observation.

-

-

-

Diesel Generator Pump checkpoints are –

-

-

-

- Diesel level in the tank,

-

-

-

- Inlet valve,

-

Related: SOP – Operation of DG Set

-

-

- Coolant in the radiator,

-

-

-

- Bypass valve position,

-

-

-

- Vibration, and physical observation.

-

-

- Always maintain the Hydrant line water pressure from 4.0 to 8.0 Kg/ Cm2

-

- Operate the Jockey pump on auto mode to maintain the desired line pressure.

-

- There are different types of nozzles used when fighting the fire.

-

- Every firefighter / trained personnel shall be familiar with the same, for better operation of the fire hydrant system.

-

-

Follow the Precaution as given below.

-

-

- Remember to RACE during a fire

-

-

- R – Rescue (Rescue in immediate danger)

-

-

-

- A – Alert (Shout Fire! Fire! And / or Dial emergency phone number 121 / 123)

-

-

-

- C – Certain content / precautions

-

-

-

- E – Extinguish / Evacuate (Extinguish small fires, evacuate, if appropriate)

-

-

- Proper precaution shall be followed when fighting the fire to avoid any slip hazard & also, use ‘danger’ road sign to face oncoming traffic.

-

- Fight the fire with your back toward an escape route. When NOT to Fight FIRE?

-

-

- The fire has spread beyond its point of origin.

-

-

-

- Remember to keep an exit to your back.

-

-

-

Stop Drop And Roll

-

-

- If clothes catch fire, it’s normal to be a bit scared, but try not to panic.

-

- By learning how to Stop, Drop, and Roll, you will have a better chance of being okay.

-

- STOP! Do not run! (Running only makes the fire bigger)

-

- DROP! (Drop to the ground or floor)

-

- ROLL! (Roll over and over until the flames smothered. Cover face with hands)

-

- You shall stop drop and roll, only when your clothes are on fire.

-

- Call the fire brigade team when fire fighting (in-house) shall not control.

7.0 ANNEXURES – FIRE SYSTEM:

Annexure 1: Fire Hydrant Inspection Register

Frequency: Monthly

Month & Year (MM / YY): __________________

| Sr. No. | Date | Check Point Details / ID No. | Inspected By | Status

Ok / Not Ok |

Remarks |

| Check Points – 1) Valve / Knob 2) Tube / Nozzle 3) Hose Pipe 4) Supply of Water | |||||

Annexure 2: Fire Extinguisher Numbering Details

Revision No. : Effective Date:

| Sr. No. | ID. No. | Location | Type | Capacity in Kg. |

Annexure 3: Extinguisher History Card

| Serial No | Type | ||

| Capacity | Year | ||

| Make | Location | ||

| HYD Test done on | |||

| HYD Test due on | |||

| Refilling done on | |||

| Refilling due on | |||

| Servicing Date | Next Due Date | Remark | Sign |

Annexure 4: Hydrant Point & Hose Reel Numbering Details

Revision No. : Effective Date:

|

Sr. No. |

ID. No. |

Location |

************************************************END************************************************

Pingback: Emergency Plan On Site - Safety SOP - Pharma Beginners