Standard Operating Procedure (SOP) for the identification of requirement, procurement, handling, issuance, and destruction of Rubber Stereos used for batch details overprinting of various products.

SOP FOR RUBBER STEREOS

1.0 PURPOSE:

-

- The purpose of this Standard Operating Procedure (SOP) is to lay down the procedure for identity, procuring, handling, issuance, and destruction of rubber stereos used for batch details overprinting on strips and blisters of various products.

2.0 SCOPE:

-

- This procedure is applicable for rubber stereos used for batch details overprinting on strip and blisters of various products at the pharmaceutical drug manufacturing plants.

3.0 REFERENCES:

-

- ICH Guideline: Q7A – Good Manufacturing Practices.

-

- In House

4.0 RESPONSIBILITY – SOP FOR RUBBER STEREOS:

-

- The production department is responsible to raise the rubber stereos indent, receipt of rubber stereos, issuance, usage and destruction of rubber stereos.

-

- The production department is responsible to maintain stereo indent detail log.

-

- Quality Assurance is responsible for cross-verify indent details.

-

- Quality Assurance is responsible for the cross-verify stereo impression.

-

- QA is responsible to ensure the destruction of rubber stereos after completion of the batch.

-

- Department Head is responsible to ensure proper compliance of SOP.

5.0 ABBREVIATIONS – SOP FOR RUBBER STEREOS:

-

- BMR: Batch Manufacturing Record

-

- BPR: Batch Packing Record ( Related: SOP for BMR / BPR Review)

-

- Dept: Department

-

- No: Number

-

- QA: Quality Assurance

-

- SOP: Standard Operating Procedure

6.0 PROCEDURE FOR HANDLING OF RUBBER STEREOS:

-

-

Procurement of Rubber Stereos :

-

-

- Rubber stereos required for the overprinting on strips and blisters on various products shall be indented by the Production department.

-

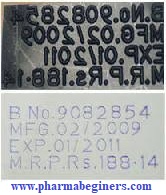

- Prior to indent the stereos, requirements like Batch No., Mfg. Date, Exp. Date, M.R.P., Lic. No. , Address and other specific requirements ( if any) shall be verified from respective BMR/BPR/ pack profile and for price from metis or their relevant documents.

-

- Mention the additional information like font size and quantity of stereos required in indent request.

-

- After filling the details of stereo indent, the production shall forward the indent request to QA for verification.

-

- After satisfactory verification by QA, Handover the indent request to production for further course of action.

-

- No overwriting, cutting on stereo Indent Sheet.

-

- In case of any, fresh indent shall be prepared for the approval process.

-

- Production shall intimate the approved stereo supplier by means of e-mail communication.

-

- Ensure the approved stereo indent sheet attached to the E-mail.

-

- After placing the indent, the production person shall fill the indent details and record the date & time of E-mail communication along with sign & date on stereo indent request.

-

- Make entries in the’ Stereo Indent detail log’ as per Annexure –1.

-

- Also, follow up if indent stereos not received within 15 days from the date of indent.

-

-

Verification and Issuance of Rubber Stereos :

-

-

- After receipt of stereos, production shall ensure the availability of the first impression sheet of all stereos.

-

- Simultaneously verification by whom shall be done for quantity and correctness of stereo against indent request and attached with the original indent request for future reference.

-

- After satisfactory preliminary verification of receipt stereos, the production person shall take the impression of each stereo on Annexure-2.

-

- In case of any stereos found to be defective with respect to alignment, cutting , indent information like B.No., Mfg, Exp., MRP and other, the set of stereos shall be rounded to indicate the not suitable for use and shall be destroyed immediately.

-

- The pieces of destroyed stereo shall not be preserved along with the other good stereos and details shall be recorded as remark in Annexure -2.

-

- In case wrong stereos received from the vendor, send the complaint form as per attachment- 3 and the complaint form shall be attached with stereo indent request. The relevant documents like complaint response from the vendor side shall be presented with the respective complaint forms.

-

- After checking the stereo impression record, production shall handover the stereo impression record to the QA for verification.

-

-

Usage of Rubber Stereos :

-

-

- After satisfactory verification of stereos, the stereos shall be placed into respective cupboard having a lock and key provision, till its issuance for indented batch for overprinting activity.

-

- The stereo impression sheet shall be attached to respective BPR for ready reference during packing.

-

- As per the packing plan, stereos shall be issued to the operator, by production person, and details of issuance shall be recorded in Annexure -2.

-

- After that, the operator shall use the required number of stereos on the printing roller and the balance quantity of stereos shall be attached to respective BPR till the completion of the batch, with the help of a self-sealing polybag.

-

- In case, if any defect found during proof checking / running, defective stereos shall be replaced with a good one.

-

- Defective stereos shall be destroyed by cutting into pieces and all cut stereos shall be preserved separately along with respective BPR till batch completion.

-

-

Proof/Impression Checking of Rubber Stereos :

-

-

- Prior to starting the packing activity, initial foil proof for the correctness of stereo impression along with alignment shall be verified by production and QA persons.

-

- Fresh foil proof shall be taken on each day, prior to start of packing operation.

-

- Additional foil proof shall be generated depends upon conditions such as stereo change, major machine breakdown, which likely to import the printing quality.

-

- After completion of batch, the machine operator shall return all the stereos to the production line supervisor.

-

-

Destruction of Rubber Stereos :

-

-

- Production person shall reconcile all stereos and destroy them by cutting into pieces with the help of seizer in presence of QA.

-

- Document the details of stereo destruction in respective batch packing record.

-

- In case of partial batch packing, the stereos shall be destroyed after completion of packing of required lot quantity.

-

- Fresh stereo shall be indented each time of packing operations of lots/ partial quantity as the batch number is likely to the suffixed alphabets like A/B/C etc.

7.0 ANNEXURES – SOP FOR RUBBER STEREOS:

Annexure 1: Rubber Stereos Indent details log.

|

Sr No. |

Product | Batch No. | Mfg.date | Exp.date | Supplier Name | Checked and Ordered By | Checked and Received By | Remarks if any | ||||

| Qty. | Sign. | Date | Qty. | Sign. | Date | |||||||

|

|

||||||||||||

Annexure 2. Rubber Stereo Impression Record Format.

| Product Name | MRP per 10 Tablets | ||

| B. No. | Incl. of all Taxes | ||

| Mfg. Date | No. of Stereos Indent | ||

| Exp. Date | No. of Stereos Received |

Annexure 3: Rubber Stereo Complaint Format.

| To | Date of Complaint | ||

| Product | Batch No. | ||

| Vender Address | Stereos indent Date | ||

| Indent No. | |||

| Stereos indent qty. | |||

| Received Qty. | |||

| Complaint Details | |||

| Prepared By: Production Person ( Sign and Date) |

Checked By: QA

( Sign and Date) |

| Closing Action : |

| Filled By: Production Person ( Sign and Date) | Checked By: QA ( Sign and Date) |

Remark:- Attach any CAPA related documents provided by the stereo vender.

Note: the complaint form shall be attached with ‘stereos Indent request’

Annexure 4: Master File of Rubber Stereo Indent.

| Name of Product | B. No. ___________

MFG. ___/______ EXP. ___/______ MRP Rs. _____ . ____ PER XX Capsules /Tablets INCL. OF ALL TAXES |

Qty.:____XX_____Nos.

Letter Size Length= 00.00 mm Width = 00.00 mm |

Annexure 5: Flow chart for Handling of Rubber Stereos.

STEP -1

| Review of Stereo Indent

(Stereo indent for the product planned) Batch no.is taken from the BMR. Mfg. and Exp. of the product assign as per SOP for “Assigning Manufacturing and Expiry Date of the product”. |

STEP -2

| After procuring the Batch Number, Manufacturing, and Expiry Date of the product. Check the price of the product from the MRP List.

In case of a new product or Batch having a suffix, Confirm the price by sending a mail to distribution. |

STEP -3

| The letter size and the number of stereos required are made as per” Master File of Stereo indent”.

Make Arrangement of letters required according to machines as per upgraded in Master File of Stereo Indent. |

STEP -4

| Production Person shall verify the Stereo Indent and cross-verified by QA. Send the indent copy to the approved Vendor through the mail.

The supplier to whom the stereos are ordered and the person checked and ordered clearly entered into the Register. |

STEP -5

| On receipt of the stereos, ordered products are checked against the copy of Indent. The stereo matched are kept and the unmatched stereos are rejected. |

STEP -6

| Stereo Impression of Individual Rubber Stereo are taken and correctness of each stereo is checked against the copy of Indent. In case of defective stereos informed to the vendor and are rejected. |

STEP -7

| Rubber Stereo impressions are rechecked by Production person and QA person for its correctness of Manufacturing, Expiry, and Price. |

STEP -8

| After proper checking stereos are stored in the cupboard under lock and key. |

STEP -9

| Stereo issuance to be done to authorized persons only. The issuance of stereo is done at the time packing |

STEP -10

| Quantity of Stereos issued is verified by production person against the stereo impression record and count the number of stereos before entering into the BPR |

STEP -11

| The required quantity of stereos required for the printing roller is issued to the operator and the extra quantity of stereos are attached with the BPR |

STEP -12

| After completion of the batch the all the stereos issued for the batch are destroyed in presence of Production and QA |

—————————————————-xxxxxxxxxxxxxxxxx—————————————————–