Standard Operating Procedure for maintenance of the building in different seasons/weather for cracks, chocked and drainage systems in a pharmaceutical manufacturing plant.

Standard Operating Procedure for maintenance of the building in different seasons/weather for cracks, chocked and drainage systems in a pharmaceutical manufacturing plant.

Building and facilities demand continue up keeping, repair works or up-gradation work for floor, wall, and ceiling. Whenever it happens painting, rack repair, floor repair, surrounding maintenance are done is called Building Maintenance.

Procedure for Building Maintenance

1.0 PURPOSE:

-

- The purpose of this SOP is to define the procedure for building maintenance.

2.0 SCOPE:

-

- This procedure is applicable to the maintenance of factory building in the pharmaceutical manufacturing plant.

3.0 REFERENCES:

-

- In house procedure

4.0 RESPONSIBILITY:

-

- Responsibility of maintenance supervisor to ensure that the works is carried out as per the defined procedure.

-

- Responsibility of maintenance supervisor to maintain the proper records.

-

- Personnel and Administration department to ensure that proper housekeeping is maintained in and around the factory buildings.

-

- Personnel and Administration department to maintain proper records

5.0 ABBREVIATIONS USED IN SOP OF BUILDING MAINTENANCE:

-

- MS : Mild Steel

-

- NA : Not Applicable

-

- PU : Poly Urethene

-

- QA : Quality Assurance

-

- SOP : Standard Operating Procedure

6.0 DEFINITION:

-

- Building Maintenance: Building and facilities demand continue up keeping, repair works or up-gradation work for floor, wall, and ceiling. Whenever it happens painting, rack repair, floor repair, surrounding maintenance are done is called Building Maintenance.

7.0 PROCEDURE FOR BUILDING MAINTENANCE:

-

-

Painting – Building Maintenance

-

-

- Carryout the painting work after any modification in civil work.

-

- Carryout the painting in manufacturing areas at least once in three years or as and when required.

-

- Use PU paints for the painting in the manufacturing area & repair the flooring with epoxy paint.

-

- All the Secondary Packing area and Quality control area painted with Plastic paint as and when required. However, Carryout the painting work at least once in three years.

-

- Paint the building from outside with cement-based External acrylic paint and white Apex paint. Carryout the painting at least once in four years.

Related: SOP for Effluent Treatment Plant (ETP)

-

- An outside agency shall carry out the painting work under the supervision of the engineer.

-

- Paint the MS structure with one coat of red oxide and two coat of Oil paint to avoid rusting as and when required. However, the painting is carried out at least once in two years.

-

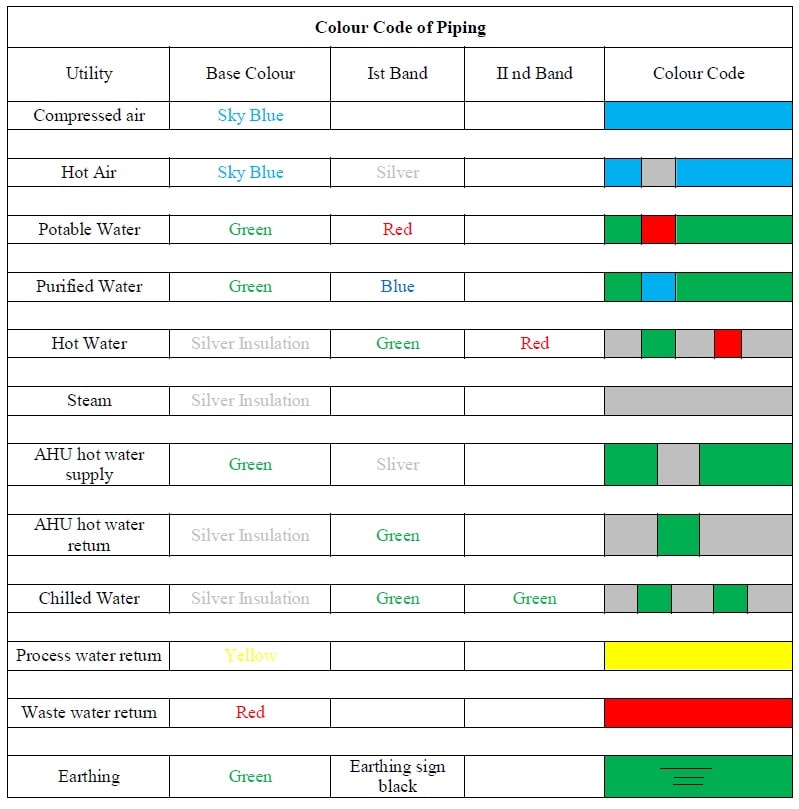

- Piping shall be painted with one coat of red oxide and two coats of oil paint to avoid rusting as and when required, However, the painting shall be carried out at least once in two years, Piping shall be painted as per defined color code Annexure-1

-

- Records of the painting are maintained as per Annexure -2

-

-

Leak checking of Roof – Building Maintenance:

-

-

- Check roofs and gutters visually for any damages at least once in a year before the commencement of the April Month.

- If required repairs shall be carried out by the maintenance department.

- Records shall be maintained as in Annexure No.3

-

Leak Checking of Pipes, Process pipes and Drainage – Building Maintenance

- Underground drains and all pipes, including process pipes of service floor area, are checked and cleaned as and when required. Checking shall be carried out at least once in the year before the commencement of the April Month.

- If required repairs shall carry out by the maintenance department.

-

- Records are maintained as in Annexure No- 4

-

-

Crack Checking of Building/False Ceiling/ Flooring – Building Maintenance

- In the manufacturing area, Cracks in the wall and false ceiling shall be checked visually once in three months.

-

-

- If required repairs shall carry out by the maintenance department.

-

- Record the inspection details as per Annexure -5.

-

-

Crack/Condition Checking of Epoxy/Kota stone Flooring –– Building Maintenance

- In the manufacturing area, flooring shall be the monitor for Epoxy at least once in a year or any modifications.

-

-

- Condition of the Kota flooring is monitored once in six-month and necessary repairs shall be carried out by the maintenance department as per the requirement.

-

- Records are maintained as the Annexure -6

-

-

Light, Fixtures Checking in manufacturing cubicles, corridor, etc. –– Building Maintenance

- Inspection of Lights, Fixtures shall be carried out after completion of Six months.

-

-

- Required repairs shall perform by the Maintenance Department.

-

- Records of inspection shall record as per Annexure -7.

8.0 DISTRIBUTION OF BUILDING MAINTENANCE SOP:

-

- Quality Assurance

- Maintenance

- Environment, Health, and Safety

9.0 ANNEXURES:

-

-

Piping Colour Code. – Annexure 1:

-

-

-

Painting Record – Annexure 2 :

-

|

Sr.No |

Name of the Area | Type of the Paint | Last Painted On | Due On | Checked By/Date | Remark |

|

|

-

-

Roof Leak Checking Records (Annexure 3)

-

|

Sr.No |

Name of the Area | Inspected On | Observation | Corrective Action Taken | Inspection |

Remark |

-

-

Pipe/Drainage leak checking records – Annexure 4:

-

| Sr.No | Description of Pipe/Drainage | Inspected On | Observation | Corrective Action Taken | Inspection Due on | Remark |

-

-

Cracks Inspection Records – Annexure 5:

-

| Sr.No | Name of the Area | Inspected On | Observation | Corrective Action Taken | Inspection Due on |

Remark |

-

-

Epoxy/Kota Flooring Inspection Record Annexure 6:

-

|

Sr.No |

Name of the Area | Inspected On | Observation | Corrective Action Taken | Inspection Due on |

Remark |

-

-

Light, fixtures Inspection Records – Annexure 7 :

-

|

Sr.No |

Name of the Area | Inspected On | Observation | Corrective Action Taken | Inspection Due on |

Remark |