SOP for GC Column Receipt, Performance Check and Storage

Standard Operating Procedure (SOP) for GC Columns, Receipt, performance check, usage, and maintenance of Gas Chromatography Column.

SOP for GC Column: Receipt, Storage, Performance Check, Uses and Care

1.0 Purpose:

-

- The purpose of this SOP is to describe the procedure for the receipt, performance check, usage, and maintenance of GC Column.

2.0 Scope:

-

- This SOP is applicable for the receipt, performance check, usage, and maintenance of GC Column at the Quality Control Department in the pharmaceutical industry.

3.0 References, Attachments & Annexures:

-

-

References:

- Certificates received along with GC Column from the manufacturer like J & W, Retake, Alltech, Supelco, etc.

-

-

- In House

-

Attachments:

- Column Inventory/Index. (Attachment –1)

-

- GC Column Utilization Register. (Attachment –2)

-

- Column Performance Check. (Attachment –3)

-

- GC Column label. (Attachment –4)

-

- Annexures: NA

4.0 Responsibilities:

-

-

The analyst shall be responsible for :

- Take column inventory, check the performance, and maintain the column as per SOP.

-

-

- Maintain the Column Usage log.

-

- Condition the column and documented as per SOP.

-

- Intimate the Head QC or Designee in case of any column abnormality.

-

Head Quality control or designee shall be responsible for :

- Evaluate the performance of Column and conditioning.

-

- Proceed for the procurement of a new column and discarding of the column.

-

- Supervise the Column performance and conditioning is followed as per SOP.

-

Quality Assurance (QA) shall be responsible for :

- To ensure the implementation of the system as per SOP.

-

Regulatory Affairs, Quality, and Plant Head shall be responsible for :

- To review and approval of SOP.

5.0 Abbreviations & Definition of terms – GC Column:

-

- Abbreviations:

-

- ID: Internal Diameter

-

- GC: Gas chromatography

-

- SOP: Standard operating procedure

-

- Definition of terms: –NA-

Also read: SOP for Audit Trail Review and Privilege Policy

6.0 Procedure – GC Column:

-

Receipt and Coding of New GC Column :

- Upon receipt of the new GC column analyst shall inspect the column for damage or breakage.

-

- In case of any damage or breakage inform to Head QC or designee and take necessary action.

-

- Upon receipt of the column, the analyst shall verify the details.

- Batch No. / Column serial No.

- Make

- Size

- Type against the purchase requisition and

- Certificate of the GC column.

- Upon receipt of the column, the analyst shall verify the details.

-

- After verification, the analyst shall allocate column no. in serial of receipt of the column and write the column no., the certificate, and put initial and date.

-

- File the certificate in the respective file.

-

- Coding/Allocation of GC Column as follows.

-

-

- GCC/YY/XXX

-

-

-

- GCC = Gas Chromatography column.

-

-

-

- YY= is the last two digits of the year

-

-

-

- XXX = serial no as 001,002,……so on. e.g the First column in the house no. in the year 2020 shall be given as GCC/20/001.

-

-

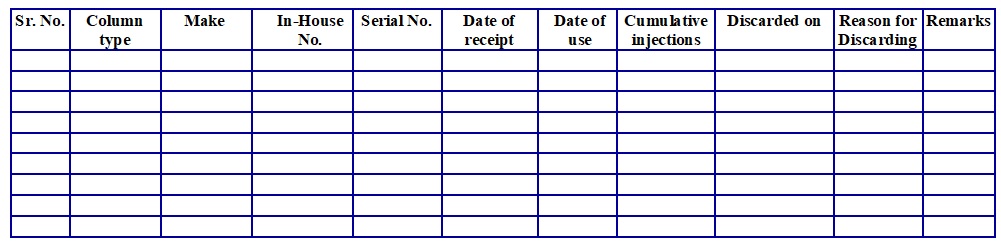

- After allocation of column no., the analyst shall make an entry in the “Column inventory/Index” (Refer attachment-1).

-

-

- For “In-house Column No., “Column Type” (Stationary phase or Brand name),

-

-

-

- “Make” (J & W, Alltech, Restake, etc.),

-

-

-

- “Column Serial No.” (Available on the column or in Certificate),

-

-

-

- “Date of receipt”,

-

-

-

- “Reference Page No. of column usage log”,

-

-

-

- (Name of Material/product),

-

-

-

- “Date in use” and

-

-

-

- “Remark (if applicable)”.

-

-

- The officer shall make an entry in the “Column inventory/Index” (Refer attachment-1) for “Discarded on”, “Reason for discard” and “Remark (if applicable)” at the time of column discard.

-

- QC Officer shall affix the “GC Column label” on the respective column box (Attachment-4) for identification purposes.

-

- The analyst shall make an entry in the “Column Utilization Register (Refer attachment-2)”

-

Usage of the GC Columns:

-

Column installation for the capillary GC column:

-

-

- For Injector end: For any new column cleave off 1-2 cm from the injector end of the column.

-

- Insert the injector end of the column into the injection port, making sure to insert it at the appropriate distance.

-

- Tighten the ferrule until the column no longer slides up or down the fitting. One-fourth of a turn past finger tight is usually.

-

- Apply carrier gas pressure at least 5psi (1kpa = 0.145psi) for 0.53 mm ID, 10psi for 0.32 mm ID, 20psi for 0.25 mm ID and 30psi for 0.20 mm ID columns.

-

- For Detector end:

-

- For any new column cleave off 1-2 cm from the detector end of the column.

-

- Wait 1 minute, then check the gas flow by dipping the detector end of the column into a vial of non-toxic solvent (Water: IPA, 50:50) and check for carrier gas bubbles.

-

- Install the detector end of the column into the detector port making sure to insert it at the appropriate distance and follow the remaining procedure as per the above-described steps.

-

- Check the leakage from the injector end and detector end by using Water: IPA, 50:50.

-

GC Column installation for Packed column:

- For Injector end:

-

- Insert the injector end of the column into the injection port, making sure to insert it at the appropriate distance.

-

- Tighten the Nuts and ferrule until the column no longer slides up or down the fitting.

-

- Apply carrier gas pressure and purge the column for at least 15 minutes.

-

- For Detector end:

-

- Check the gas flow by dipping the detector end of the column into a vial of non-toxic solvent (Water: IPA, 50:50) and check for carrier gas bubbles.

-

- Install the detector end of the column into the detector port making sure to insert it at the appropriate distance and follow the remaining procedure.

-

- Check the leakage from the injector end and detector end by using Water: IPA, 50:50.

-

-

Column conditioning:

- For any new column purge, the column with carrier gas for 15 minutes keeping the detector end open.

-

-

- Increase the temperature gradually from 25°C or ambient at the rate of 10°C/min. or

-

- Suitable rate to reach the column temperature below 25°C of the maximum temperature of the column.

-

- Maintain the achieved temperature for about 2-3 hrs. or till the baseline gets stabilized.

-

- In the case of thermally stable methyl- and phenyl-substituted polysiloxane,

-

-

- A special sequence increases inertness and efficiency; maintain the column at a temperature of 250° for 1 hour, with helium flowing, to remove oxygen and solvents.

-

-

-

- Stop the flow of helium, heat at about 340° for 4 hours, and then reduce the heating to a temperature of 250°, and condition with helium flowing until stable or condition the column as per column specification/manufacture specification.

-

Conditioning Steps of GC Column

-

- Step:1

-

- Purge the column with carrier gas for 15 minutes keeping the detector end open.

- Step:2

-

- Increase the temperature gradually from 25°C or ambient at the rate of 10°C/min or a suitable rate using nitrogen as the carrier gas.

- Step:3

-

- Achieve the column temperature below 25°C of the maximum temperature of the column recommended by the manufacturer.

- Step:4

-

- Maintain the achieved temperature for about 2-3 hrs. or till the baseline gets stabilized.

- Step:5

-

- Allow the column oven temperature to cool about 25ºC

-

Performance check of GC Column:

- Before dedicating the column for a particular material/product check the performance of the column as per Attachment-3.

-

- If the performance/system suitability of GC Column found satisfactory. Dedicate the column to that particular product/test.

-

- In case the performance of the column is not found satisfactory as per the procedure described in attachment-3,

-

- The analyst shall perform the analysis of other material/product for which the column needs to dedicate and if the system suitability parameters of the respective material/product are satisfactory, the column shall be dedicated to that material/product.

-

- In this case, the analyst shall attach the system suitability chromatogram along with the column certificate.

-

- Upon satisfactory system suitability check, Head QC or designee shall dedicate the column for specific material/product, and the “Date in use” column shall be filled in “Column Inventory/Index”.

-

- In the case of system, suitability is not achieved due to the presence of drift, hump or ghost peak, etc in the baseline.

-

- Then analyst shall carryout conditioning of the column and checks the system suitability for the material/product for which it is dedicated.

-

- After conditioning, if system suitability parameters of material/product as per respective Standard Testing Procedure (STP) is found satisfactory continue the usage for analysis.

-

-

Note

- If, system suitability parameters of material/product as per respective STP are found unsatisfactory discontinue the column usage and discard the column after authorization of Head-QC or designee.

-

-

- In case a column of different make (i.e. Other than dedicated make) required to use for the analysis it shall be used after ensuring that the stationary phase, % of stationary phase, column length, and ID of different make column are similar to the dedicated column or the column that is mentioned in the ATP.

-

- In this case system suitability criteria as per respective standard tests, the procedure must be checked and ensured.

-

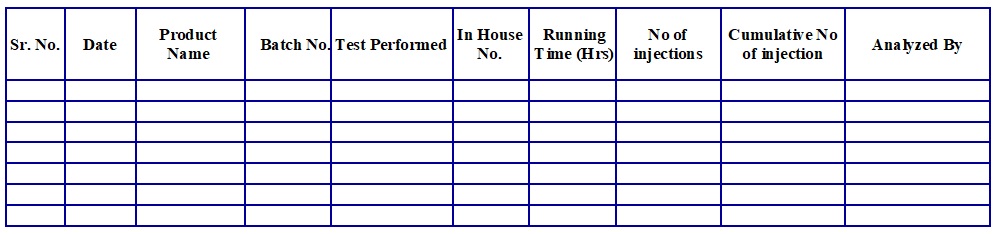

GC Column usage:

- Make necessary entries on every usage of the column in respective Column Usage log for “Sr. no.”, “Date” “Product Name”, “B. No./A.R No.”, “Test Performed”, “ Running Time Hrs”, “No. of Injection” “Cumulative No. of Injections” “Analyzed By” and Remarks. (If column performance is found as per the requirement then use “Satisfactory”. If column performance is not found as per the requirement mention Specific reason (Like Theoretical plates or Tailing factor or resolution do not comply etc.) (Attachment – 2)

-

- After completion of the analysis, allow the column to cool to room temperature (in column oven), disconnect the column, fix the column ends, and keep the column at the designated place.

-

Discarding of the GC Column:

- Discard Column, in case of Non- compliance of system suitability parameters against the material/product system suitability.

-

- Head QC or designees shall make an entry of “DISCARDED ON”, and “REASON FOR DISCARD” in “Column Inventory/Index” also in “GC Column Usage Log” in the “Remarks” column.

-

Precautions during uses of GC Column:

- Always use a capillary cleaving tool of other scoring devices for cleaving.

-

- Carefully insert the column end in the ferrule hole.

-

- Install the column to the GC column oven hanger.

-

- Take care that the column should not touch the sides of the column oven.

-

- Never heat the column without ensuring the carrier gas is flowing through the column.

-

- Always maintain the detector temperature higher than the maximum column operating temperature. So that the column elution will not condense in the detector unless otherwise follow the condition as per the respective analytical procedure.

Column Inventory/Index. (Attachment 1)

GC Column Utilization Register (Attachment 2)

Column Performance Check. (Attachment 3)

| Column No.: | |

| Name of Product/Material: | |

| Name of Test: | |

| Reference of ATP/Pharmacopoeia: | |

| B. No./A.R.No.: |

| Stage: In-process/Finished product/Method transfer/Stability/Method validation (Specify if any) | ||

| Procedure: Carry out the injections as per the requirement of the respective test of product/material in ATP / pharmacopeia. Record and review the chromatograms and report the System suitability results in the following table. Compare the results against the system suitability criteria and confirm whether the column performance is satisfactory/unsatisfactory for the analysis of the particular test of the product. Attach the system suitability chromatogram along with the “Column performance check” and submit for checking. |

||

| Acceptance criteria | Results | |

| SYSTEM SUITABILITY CRITERIA | ||

| a. Theoretical Plates | ||

| b. Tailing Factor | ||

| c. Resolution | ||

| d. Peak shape | ||

| e. Other (if any) RSD% | ||

| Conclusion: The system suitability parameters as per the requirement of the respective test of product/material in ATP / pharmacopeia is Satisfactory / Not Satisfactory.

So the Column is qualified / not qualified for the intended use. |

| Remarks: |

| Analyst : | Checked By : |

| Date : | Date : |

Attachment –4: GC Column label.

| Column Type : ______________________

Dimension of Column: _______________________ ( Length*ID * particle size) Column No. : ________________ Dedicated For : _______________________ |

Next to read : (more…)